At SC Industries we have over 75 years of experience producing reliable and long-wearing bearings and bushings.

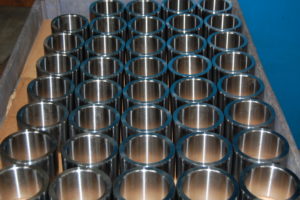

We have been known as the “Bushing Specialists,” which is why customers in the heavy-duty vehicle industry continually engage us to provide long-wearing, high-reliability products. In the following project, we fabricated this hardened steel bearing bushing for use in mining equipment.

Constructed from 521000 bearing steel for its hardness and wear properties, it featured dimensions of 7-1/4″ in length x 6-1/2″ in width x 7-7/8″ in height. Close tolerance precision machining resulted in a high level of dimensional integrity, and a secondary centerless grinding process enabled us to achieve accuracies of ±0.0004″ as well as a 16 RMS surface finish.

Our unsurpassed understanding of metal properties and characteristics enabled us to heat treat the component to a uniform hardness with no distortion to the workpiece. In addition to hardness testing, we applied quality assurance using precision calibrated digital gages to accurately measure the I.D and height.

In the field, the low friction surface combined with outstanding hardness properties provided a high-reliability and low maintenance solution for this rugged and demanding environment. Today, we continue to produce this product in various quantities.

If you are interested in learning more about this project, you can contact us today.