Quality

SC Industries, Inc. is currently ISO 9001:2015 registered.

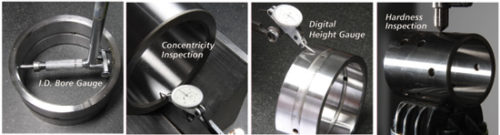

SC Industries’ Quality Assurance Program utilizes the most advanced techniques and inspection equipment in the industry. We perform consistent quality control measures from the moment materials come into final inspection.

Our sampling plans are based on ANSI/ASQ Z1.4 (2008) using normal sampling and an acceptance level of 1.0. We employ Statistical Process Control and our in-house Calibration System is compliant to Z540-1 and MIL STD 45662A. A Production Part Approval Process (PPAP) is available upon request.

You can download a copy of our current ISO Registration here.

Our Inspection Equipment includes:

- Bore Gauges from .250 to 16 Inches

- Height Stands

- Mahr Metrology Height Gauges

- Micrometers Up to 17 Inches

- Plug Gauges from .011 to .500 Inch

- Thread Rings and Thread Plug Gauges, As Needed

- Hardness and Effective Case Testers, Certified at 6-Month Intervals by UTS, and Verified Daily

- Federal Surface Analyzer

- Magnaflux and Dye Penetrant Testers

Where necessary, we can generate reports, including final inspection, on our forms or yours. Inspection results are saved to computer files, and backed up daily. All records are maintained and stored for a minimum of 3 years.