Our 75+ years of experience in producing precision hardened metal bushings are supported by the equipment we utilize.

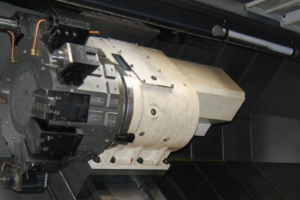

This includes Multi-Axis CNC Turning Centers, Milling, and Centerless & Internal Grinding. We ensure precise tolerance, with grinding precision to required size, micro-finish, and T.I.R.

At SC Industries we utilize the latest Multi-Axis CNC Turning and Machining Centers, in our production processes. As a leading bushing specialist, we can efficiently create hardened and ground bushings and bearings, and general machined component parts in a variety of configurations necessary for your applications.

We have a solid background in metals science and an in-depth knowledge of the material properties of all types of steel, including hardened steel alloys, as well as aluminum and bronze metals. We utilize only premium quality, certified materials to ensure consistency in performance. Our carefully applied heat treatment processes are combined with external and in-house metrology inspections to ensure your performance specifications are met.

For more detail, please see the table below. Contact us today to learn more about how our precision machining services can benefit your next machining application.