How do I choose bushing material?

Comments Off on How do I choose bushing material?

When it comes to selecting the right bushing material, the options can seem overwhelming. From different materials to varied applications, knowing which bushing is appropriate for your needs is essential for performance and longevity.

Whether you’re working with a Steel Bushing, a bushing material for a steel shaft, or another type, understanding your options is key. This guide explores the most common types of bushings, materials, and the factors to consider when choosing the perfect fit.

How many types of bushings are there?

Bushings come in many forms, each tailored to specific applications. The following are the most common types you’ll encounter:

Steel Bushing Sleeve

A Steel Bushing Sleeve is one of the most common types, known for its durability and strength. These bushings are often used in construction, industrial machinery, and other heavy-duty applications. Steel offers a strong foundation that withstands high loads, making it ideal for environments with high friction and wear.

Bronze bushings

Bronze bushings provide excellent wear resistance due to their hardness and ability to withstand high temperatures. They are widely used in machines that demand consistent performance under extreme conditions. Their self-lubricating features, when combined with oil or grease, make them especially popular in automotive and manufacturing industries.

What are the different types of bushing materials

Bushings are manufactured using a wide array of materials, each offering unique benefits. Some of the most commonly used materials include:

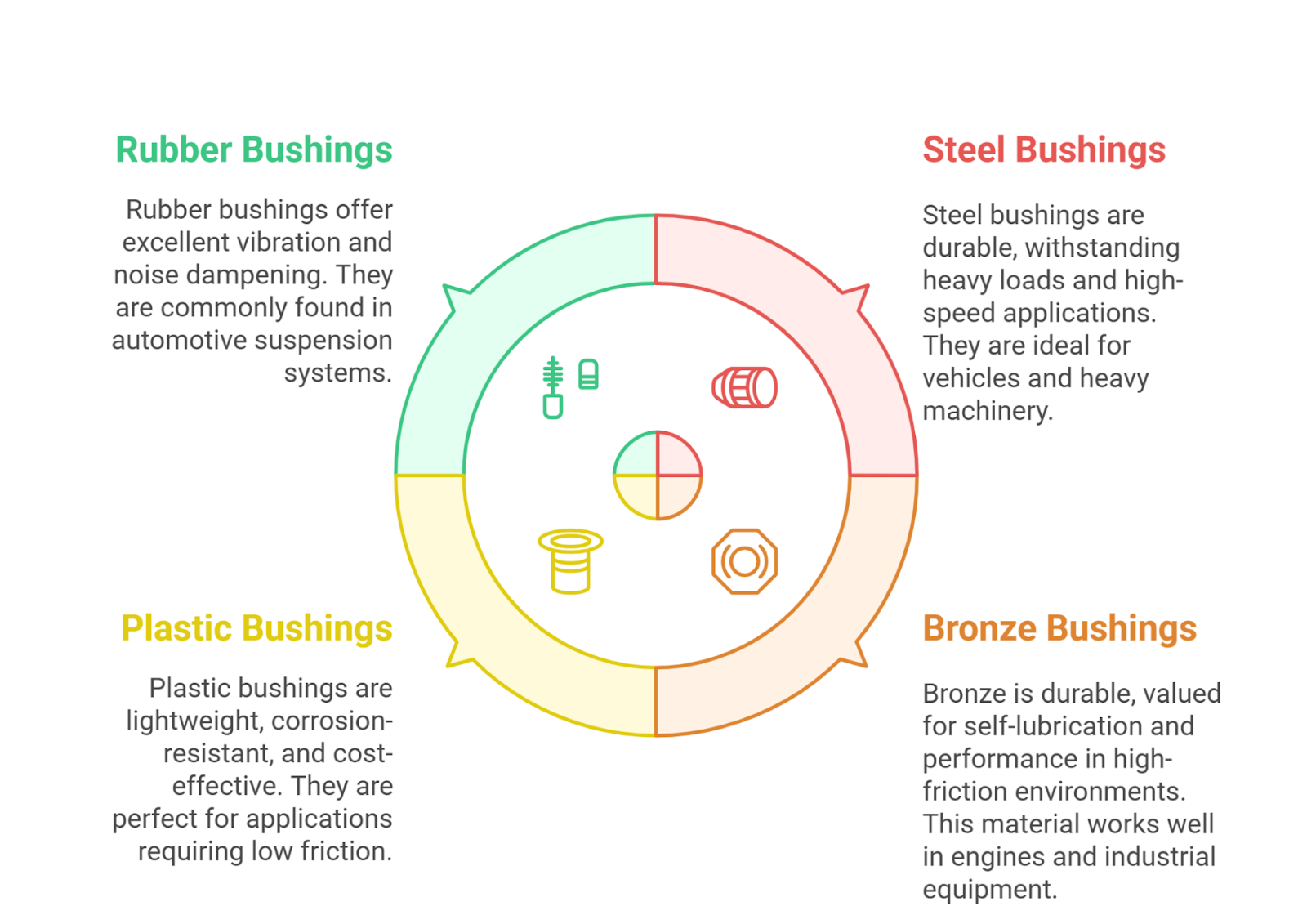

Steel

Steel bushings are highly durable, withstanding heavy loads and high-speed applications. They are ideal for use in vehicles, heavy machinery, and construction equipment, where reliability is paramount.

Bronze

Bronze is another highly durable material, valued for its self-lubricating abilities and performance in high-friction environments. This material works well in engines and industrial equipment.

Plastic

Plastic bushings are lightweight, corrosion-resistant, and cost-effective. While not as strong as steel or bronze, they are perfect for applications requiring low friction, such as household appliances or light machinery.

Rubber

Rubber bushings offer excellent vibration and noise dampening, commonly found in automotive suspension systems and industrial mounts.

Which material is best for bushings

Choosing the best material for a bushing largely depends on your specific use case. Here’s an in-depth look at the considerations involved:

What is the strongest bushing material for cars

When it comes to vehicles, the strongest bushing material is usually steel or bronze. Cars often demand bushings capable of withstanding high loads, friction, and temperature. Steel bushings excel in structural components like suspension systems, while bronze bushings are excellent in components like steering shafts where lubrication and smooth operation are vital.

Plastic bushing material for steel

A plastic bushing material for steel applications is a great choice when weight reduction, cost efficiency, or corrosion resistance is a priority. These bushings often contain composite or polymer materials that reduce friction and extend the service life of a steel shaft. Plastic bushings work well in environments where moisture exposure is a concern, as they resist rust and corrosion better than metal counterparts.

How do I choose bushing material

Choosing the right bushing material depends on several factors. Here’s what you should consider:

- Load and Stress

Assess the amount of load the bushing will support. Steel Bushing types are better for high-stress applications, while plastic works well for moderate loads. - Friction and Wear

For parts with constant motion, a self-lubricating material like bronze reduces wear and tear over time. - Environment

Consider the working environment. Is it exposed to moisture, high temperatures, or chemicals? Materials like plastic and rubber perform well in corrosive or extreme conditions, whereas steel offers strength and reliability. - Budget

While bronze bushings may be durable, they can also be costlier. For low-budget projects, plastic serves as a lightweight, economical alternative. - Lifespan

Choose materials suited to the desired longevity. Steel and bronze have longer lifespans, while rubber and plastic may require more frequent replacement.

Ultimately, your choice should align with the specifics of your project, carefully balancing performance, durability, and cost. Consider the level of performance required, the environmental conditions it will face, and your budget constraints to ensure you select the most suitable option for long-term success.

Selecting the right bushing material is crucial for achieving efficiency, durability, and cost-effectiveness in any application. Whether it’s a Steel Bushing, bushing material for steel shaft, or another type, understanding the differences in material strengths, weaknesses, and applications guides you towards the best choice.

If you’re unsure which bushing material suits your project, don’t hesitate to contact us for a consultation. For more on bushings and their uses, visit our Steel Bushing Guide.

What Material is Best for Bushings?

Comments Off on What Material is Best for Bushings?

Bushings play a critical role in reducing friction between moving parts, ensuring smooth operation, and prolonging the life of machinery. But determining the best material for bushings requires understanding different materials and their unique properties.

Whether you’re dealing with a Steel Bushing or choosing a bushing material for steel shafts, selecting the right material can make all the difference. Below, we’ll explore the options available and pinpoint what works best in various settings.

What Are the Raw Materials for Bushing?

The raw material used in fabrication is the key to bushing functionality. Various shaft bushing types exist, tailored to handle diverse applications. Let’s break them down:

- Bronze Bushings: Known for their durability and excellent wear resistance, bronze bushings are suitable for applications involving high loads and slower speeds. They’re commonly used in heavy machinery and industrial equipment.

- Plastic Bushings: These are lightweight, corrosion-resistant, and require no lubrication, making them a budget-friendly alternative for environments prone to moisture. They perform well in lighter load applications.

- Steel and Steel-Backed Bushings: Steel bushings, often with a backing of bronze or PTFE coating, provide robustness and heat tolerance. They’re preferred for high-stress and high-temperature environments.

- Graphite Composite Bushings: Infused with lubricating properties, these bushings are ideal for extreme operating condition applications like high temperatures, or where standard lubrication isn’t feasible.

Understanding shaft bushing types helps in pairing the right material with the application it is intended to support. The correct choice ensures efficiency and longer lifespans for the equipment.

How Do I Choose a Bushing Material?

Choosing the right bushing material isn’t just about durability. It’s about balancing load capacity, environment, and cost. Here are the main types of bushing materials and what you need to consider when selecting one:

- Bronze

Bronze bushings are typically favored for heavy machinery due to their strength, resistance to wear, and ability to withstand heat. They are commonly combined with lubricants to reduce friction.

- Plastic

If you need a low-maintenance solution, plastic bushings shine in moisture-rich or corrosive environments. While they may not handle extreme loads as effectively, they are quieter and require minimal upkeep.

- Steel

Steel bushings, especially with coatings or mixed materials, are highly durable and capable of bearing heavy loads in rigorous settings. Steel typically requires lubrication to avoid wear.

- Composite Materials

Advanced materials like PTFE composites or carbon-graphite bushings cater to specific needs like low friction, self-lubrication, or enhanced longevity in extreme operating environments.

The best match depends on the load, operating environment, and life expectancy of the bushing. Evaluating these factors will guide your decision.

What is the Best Material for Bushings?

When choosing the best material for bushings, context is everything. Each material excels in specific applications:

- For heavy-duty industrial use, bronze bushings are often the prime choice due to their excellent load-bearing capacity and heat resistance.

- If seeking a low-maintenance option, plastic bushings are your go-to, especially in corrosive environments.

- For high-stress, high-heat scenarios, steel bushings reinforced with PTFE are unmatched, offering durability with reduced wear and tear.

Ultimately, the best material for bushings depends on the operating environment. For example, if you’re working with a bushing material for a steel shaft, the high load and rotational stress handling capabilities of steel or bronze may be the optimal solution.

What Are the Disadvantages of Bronze Bushings?

Although bronze bushings are widely used across industries, they come with a few drawbacks:

- Lubrication Dependency

Bronze bushings require regular lubrication to function efficiently. Ignoring this maintenance responsibility can lead to early wear and tear. - Cost

Bronze tends to be more expensive compared to other materials like plastic, which might be a limitation for budget-conscious projects. - Limited Speed Handling

While bronze excels under heavy loads, high-speed applications can cause overheating and reduced lifespan.

Understanding the limitations of bronze bushings ensures they are used appropriately while avoiding unsuitable applications, which could lead to premature failure.

Final thoughts

Selecting the right material for bushings is critical to ensuring the performance, efficiency, and longevity of your machinery. Bushings act as key components in reducing friction, supporting loads, and minimizing wear in moving parts. Whether you opt for bronze bushings, plastic options, or advanced composite materials, your choice should be tailored to the specific demands of the application, such as load capacity, operating temperature, environmental conditions, and required durability.

If you’d like personalized advice or further guidance on selecting the best material, contact us today! Our team of experts is ready to help you identify the Steel Bushing, bushing material for steel shafts, or any other solution to suit your unique requirements. Whether you’re optimizing performance or boosting machine reliability, we’re here to help.

Don’t compromise on quality—make the right choice for your bushings! Contact us now to learn more and get started.

Hardened Steel Sleeve Bushings

Comments Off on Hardened Steel Sleeve Bushings

Hardened Steel Sleeve Bushings

Hardened steel sleeve bushings play a critical role in various industries, from automotive and construction, to heavy machinery and manufacturing. These components are engineered to reduce friction, enhance durability, and deliver long-lasting performance in high-stress, high-load environments. Designed to protect machinery and equipment from excessive wear, they ensure reliable operation even under the most demanding conditions, minimizing downtime and maintenance costs.

What sets hardened steel sleeve bushings apart is their precision engineering, high-quality materials, and ability to withstand extreme temperatures, pressure, and abrasive forces. This guide delves deeper into their design, materials, applications, and sizing requirements, giving you a comprehensive understanding of these essential components.

At SC Industries, we take pride in crafting precision-engineered Steel Bushing solutions that meet the highest performance standards. Our products are made using premium-grade materials to ensure exceptional strength, resistance to wear, and extended operational life. Whether you need standard off-the-shelf options or fully customized bushings tailored to your unique specifications, we’ve got you covered with a wide range of solutions designed to optimize your equipment’s performance and longevity. Explore how our expertise can support your industrial needs today!

What Makes a Good Bushing

When considering bushings, quality is key. A superior bushing must meet demanding industrial performance standards. Here’s what sets high-quality hardened steel sleeve bushings part from other alternatives:

- Durability: Hardened steel ensures long-lasting performance by resisting wear, tear, and deformation – even under high-stress conditions. This durability means your equipment stays reliable over time, reducing the need for frequent replacements and minimizing downtime. With less risk of failure, you can focus on productivity instead of maintenance.

- Precision Engineering: A good bushing is meticulously designed and manufactured to fit seamlessly into your machinery. This precise fit eliminates unnecessary movements, vibrations, or misalignments that can lead to inefficiencies or even damage. By ensuring smooth and consistent operation, precision-engineered bushings can significantly boost the overall performance and lifespan of your equipment.

- Shock Absorption: Durable bushings are specifically designed to handle heavy vibrations and absorb shocks during operations. This helps reduce strain on other machine components, preventing premature wear and tear. By stabilizing the equipment and minimizing vibrations, these bushings enhance machine performance while promoting a quieter, more efficient operation.

- Heat Resistance: High-grade bushings are built to withstand extreme temperatures, ensuring they maintain functionality and performance in even the most demanding environments. Whether your machinery operates in high-heat industrial setups or outdoor conditions with fluctuating temperatures, heat-resistant bushings provide the reliability needed to keep operations running smoothly and efficiently.

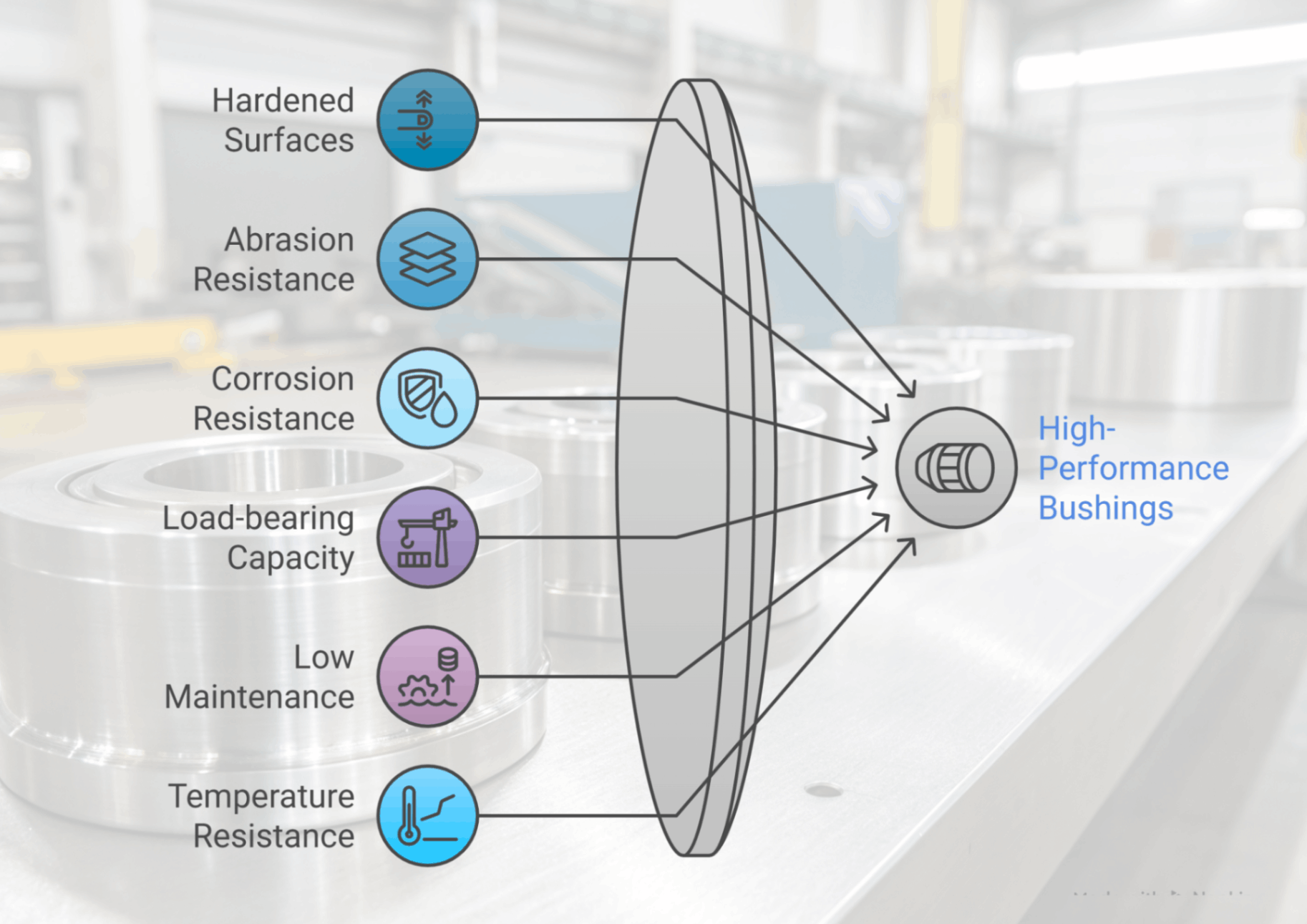

This simple flow diagram highlights the interconnected features and benefits of high-grade bushings, illustrating their importance in machinery performance and durability.

With over 75 years of experience, SC Industries specializes in manufacturing hardened steel sleeve bushings that meet and exceed these rigorous standards. Our expertise in precision engineering ensures products that deliver exceptional durability and performance. Learn about our precision machining services here.

What Are the Sizes of Bushings

Hardened steel bushings by size are engineered to meet a wide range of mechanical needs, from compact, precision components to large-scale industrial applications. Bushings are manufactured in a wide range of sizes to meet the unique requirements of different types of machinery. From precision components for small devices to robust bushings for heavy-duty industrial systems, each size is designed to ensure optimal performance and durability. At SC Industries, we pride ourselves on offering an extensive selection so you’ll always find the perfect fit for your equipment needs.

| Type | Description | Applications | Customization |

| Precision Bushings | Designed for tight tolerances, ensuring high accuracy using advanced CNC and grinding technologies. | Aerospace, robotics, and precision-based industries. | Built for precise applications, not typically customized. |

| Hardened Steel Bushings | Durable bushings made from hardened steel, available in various sizes from small sleeves to large industrial solutions. | General industrial use and heavy-duty applications. | Custom sizing is available to meet unique application requirements. |

What Are Bushings Usually Made Of

Bushings are crafted from a variety of materials, each offering unique properties suited for different applications. Common options include metals like bronze and steel for durability, polymers such as nylon for lightweight and low-friction needs, and composite materials that combine strength with flexibility. However, not all materials perform equally, so selecting the right one depends on factors like load, speed, and environmental conditions.

- Bronze is widely recognized for its excellent self-lubricating properties, particularly in lower stress applications. This makes it a reliable choice for environments where regular maintenance is challenging or where traditional lubrication methods are difficult to apply. It is commonly used in bushings, bearings, and other components that require consistent performance with minimal upkeep over time.

- Polymers are an ideal solution for applications that prioritize lightweight and corrosion-resistant materials. These polymers perform exceptionally well in wet or chemically exposed environments, making them suitable for industries like medical devices, marine equipment, and chemical processing. Additionally, their lightweight nature helps reduce the overall weight of components, improving efficiency and reducing energy consumption in various systems.

- Steel and Hardened Steel offer unparalleled durability and strength, making them the go-to choice for applications subject to heavy loads, high impacts, or extreme wear and tear. They are essential in heavy-duty machinery, construction equipment, and industrial applications where reliability and long service life are critical. Hardened steel in particular provides enhanced resistance to abrasion and deformation, ensuring optimal performance even under the harshest conditions.

At SC Industries, our expertise lies in producing hardened steel sleeve bushings and custom steel bushings engineered to handle the toughest challenges in demanding environments. Whether you need resilience, precision, or custom solutions, we’ve got you covered. Explore our portfolio of bearings and bushings to learn more about how we can meet your specific needs.

How to Select Bushing Material

Choosing the right bushing material for your application improves operational efficiency and longevity. Here’s a guide for selecting materials when working with a trusted steel bushing manufacturer like SC Industries:

- Load Requirements: Heavy machinery relies on components that can withstand extreme stress, which is why hardened steel sleeve bushings are an excellent choice. Their superior strength ensures durability even under constant heavy loads, making them ideal for high-demand applications such as construction, mining, and manufacturing equipment.

- Friction Levels: Reducing wear and tear is critical for the longevity of your machinery. Depending on your specific application, opting for pre-lubricated bushings can significantly lower friction levels, helping to prevent damage and maintain smooth operation over time. This is especially useful for equipment that undergoes frequent or continuous movement.

- Environmental Factors: The surrounding environment plays a key role in bushing performance. In corrosive or harsh settings such as marine or chemical environments, hardened steel with protective coatings offers added resistance to rust and corrosion, ensuring your equipment lasts longer and performs reliably.

| Material | Key Characteristics | Applications |

| Bronze | High wear resistance, self-lubricating properties | Bearings, electrical connectors |

| Hardened Steel | Extremely strong, resistant to high loads and impacts | Construction, industrial machinery |

| Polymer | Lightweight, corrosion-resistant, low-friction | Automotive, aerospace, and medical devices |

| Graphite-Embedded | Exceptional lubricity, high-temperature performance | High-heat applications, heavy machinery |

Unsure of the best choice for your needs? Contact SC Industries, a trusted bushing maker near me, for expert guidance on materials tailored to your unique industry requirements. We’re here to help you make the right decision.

What Steel Are Bushings Made Of

Steel bushings – particularly those made from hardened steel – are renowned for their exceptional strength, durability, and adaptability across a wide range of applications. Engineered to withstand extreme conditions, these components excel in high-stress environments where reliability is critical. Their resistance to wear, corrosion, and heavy loads makes them an invaluable asset in industries such as automotive, construction, manufacturing, and aerospace.

Hardened steel bushings are designed to provide long-lasting performance while minimizing maintenance needs, which is why they are a go-to solution for demanding operations. They deliver consistent results even under prolonged use, and can be trusted to keep machinery running smoothly with minimal downtime.

Here’s why hardened steel bushings are so popular:

- Heat-treated to significantly increase surface hardness, these bushings are engineered for long-term durability and exceptional resistance to wear—even under high-friction and continuous-use conditions. This process ensures they maintain their structural integrity, even in the most demanding applications.

- Perfect for custom bushing sleeve designs, these components are specifically built to excel in abrasive, high-load environments where standard bushings might wear out or fail prematurely. Their ability to withstand harsh operating conditions makes them a reliable choice for heavy-duty machinery and equipment.

- Designed with an excellent performance-to-weight ratio, these bushings are ideal for precision systems where strength, efficiency, and reduced weight are critical. Whether used in industrial, automotive, or aerospace applications, they deliver reliable performance without compromising on efficiency or durability.

At SC Industries, we specialize in manufacturing custom steel bushings tailored to your specific requirements. From design to production, our experts ensure that every product is precision-engineered to meet your needs. Whether you’re dealing with high-pressure systems or seeking long-lasting performance in heavy-duty operations, our bushings will deliver. View our range of custom capabilities here.

How Do You Increase the Hardness of Steel

The hardness of steel plays a crucial role in ensuring the durability and performance of hardened steel sleeve bushings, particularly in demanding applications. At SC Industries, we focus on delivering high-quality products, using time-tested methods to enhance steel hardness. These methods are designed to improve wear resistance, extend the lifespan of the bushings, and ensure reliable performance under extreme conditions. Our commitment to precision and quality guarantees our bushings meet the highest industry standards, providing consistent results for a wide range of applications.

- Heat Treatment: Steel is heated to a high temperature and then cooled rapidly through a process called quenching. This improves surface hardness by altering the steel’s microstructure, making it more durable and wear-resistant for heavy-duty applications.

- Tempering: After quenching, the steel is reheated to a specific temperature and then cooled again. This process balances hardness with flexibility, reducing brittleness while maintaining strength. It’s a crucial step for achieving ideal performance in components exposed to high stress.

- Case Hardening: This process creates a tough, wear-resistant outer layer while maintaining a softer, more flexible core. It’s especially useful for components like custom bushing sleeves, which demand both durability and adaptability. At our state-of-the-art facilities, we specialize in providing precise hardening solutions tailored to the unique requirements of even the most complex and demanding projects. Learn more about our machining services.

What Elements are Used to Harden Steel

Chemical processes play a critical role in the manufacturing of hardened steel bushing products, ensuring both their durability and high-performance capabilities. These processes involve the precise incorporation of key elements to significantly enhance the material’s properties, making them suitable for demanding applications.

- Carbon, absorbed into the steel surface during a process called carburizing, is essential for improving surface hardness. This heat treatment process diffuses carbon into the outer layer of the steel, creating a tougher surface that withstands high levels of stress, impact, and friction. This makes the bushings ideal for heavy-duty machinery and applications where wear resistance is crucial.

- Chromium and Molybdenum are added to the steelto further enhance performance. Chromium contributes to corrosion resistance by forming a protective oxide layer, while also improving the steel’s hardness and wear resistance. Molybdenum helps the material resist deformation under high temperatures and enhances its overall strength. Together, these alloying elements ensure the bushings maintain their reliability; even in harsh environments with exposure to heat, moisture, or abrasive conditions.

These carefully controlled chemical processes result in bushings that are not only durable but also capable of delivering consistent performance in challenging operating conditions.

At SC Industries, we combine these advanced processes with precision engineering to produce the highest-quality materials for our hardened steel sleeve bushings. Additionally, we offer the flexibility to create custom steel bushings tailored to unique and demanding applications, meeting specific project needs with accuracy and expertise. Whether you need standard parts or specialty solutions, we are ready to deliver. Contact us to discuss your project requirements.

Conclusion

Hardened steel sleeve bushings are an indispensable part of many industries, delivering top performance and reliability under demanding conditions. At SC Industries, we take pride in our over 75 years of excellence, creating precision-engineered solutions that last.

Whether you need standard precision bushings or custom bushing sleeves, SC Industries has the expertise and resources to deliver. As one of the leading steel bushing manufacturers, we are committed to delivering high-performance components that meet the most rigorous requirements. Explore our precision machining services, cutting-edge technology, and extensive portfolio today to see how we can meet your needs.

Get in Touch

Start optimizing your machinery with the best bushings in the business. Contact SC Industries now for superior quality and performance.

Understanding Bushings: A Comprehensive Guide

Comments Off on Understanding Bushings: A Comprehensive Guide

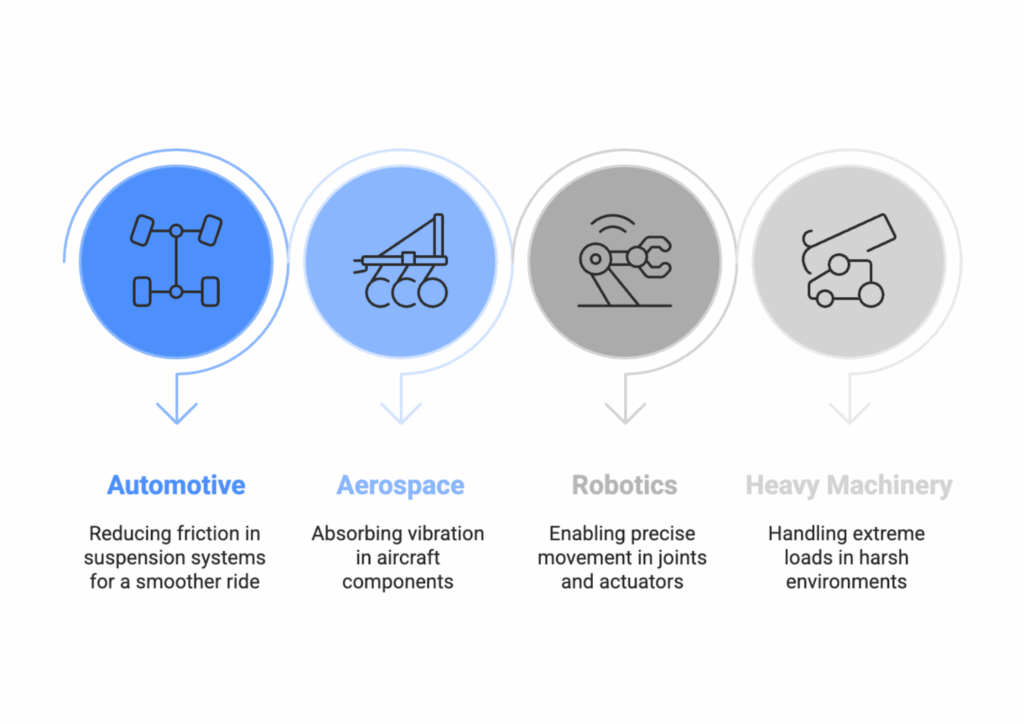

Bushings are integral components used across various industries due to their versatility and importance in ensuring proper equipment functionality. From automotive systems to mechanical equipment to electrical applications, bushings play a vital role in reducing friction, absorbing shocks, and ensuring smooth operations.

But what exactly are bushings, how do they work, and how do they compare to other components like bearings? This guide will break down their functions, applications, and advantages to give you a clear understanding of these essential components.

What is a bushing vs bearing?

Although bushings and bearings serve similar purposes, their design and operation make them distinct. Both help minimize friction and enable smooth motion between two surfaces, but they accomplish this in different ways:

Bushings are sleeve-like components, often cylindrical, that act as a sliding surface between two parts. They’re made from materials such as metals (e.g., bronze or brass), rubber, or polymers. Bushings are simple and cost-effective, often favored in systems where heavy loads and slower speeds are involved.

In contrast, Bearings include rolling elements like balls or rollers. These components are designed to minimize friction more effectively, making them ideal for high-speed, low-load applications where precision is critical.

Key Differences:

- Construction:

- Bushings are solid, cylindrical components.

- Bearings contain rolling elements that assist in reducing friction.

- Use Cases:

- Bushings work well in low-speed systems with heavy loads and are easier to replace.

- Bearings suit high-speed machinery requiring greater precision and efficiency.

When weighing bushings vs. bearings, it’s crucial to evaluate the demands of your system to make the right choice. Bushings excel in durability and cost-effectiveness, while bearings are more suitable for high-precision environments. In many designs, you’ll also find hybrid terms like bearing bushing sleeve used to describe components that combine features of both.

Material Selection and Innovation in Bushings

In recent years, advancements in materials science have led to the development of high-performance bushings that outperform traditional options. For instance, composite bushings made from thermoplastics reinforced with glass or carbon fibers offer exceptional wear resistance and low maintenance.

These innovations make bushings more adaptable across diverse environments such as aerospace or renewable energy sectors, where durability and performance are non-negotiable.

Are Bushings Better Than Bearings?

Determining whether bushings are “better” than bearings largely depends on the specific application. Each component has its strengths:

Advantages of Bushings:

- Durability: Bushings made from materials like bronze or brass are highly resistant to wear and can withstand harsh operating conditions.

- Cost-Effectiveness: They are generally more affordable than bearings and provide enhanced long-term value in many systems.

- Simple Replacement: Replacing bushings tends to be straightforward, reducing downtime during maintenance.

- Versatility: Bushings can function effectively in extreme environments, including high-temperature or corrosive situations.

Advantages of Bearings:

- Low Friction: Bearings significantly reduce friction, making them ideal for high-speed applications.

- Precision: Their design allows for greater accuracy in movement and alignment.

- Higher Speed Performance: Bearings perform best in setups with high rotational speeds and lighter loads.

Maintenance and Lubrication Considerations

Maintenance is a critical factor when deciding between bushings and bearings. Bushings often require less frequent lubrication and can operate under marginal lubrication conditions, making them ideal for hard-to-reach areas. Some modern bushings are even self-lubricating, incorporating materials like PTFE or graphite that reduce friction without external lubricants. Bearings, while efficient, typically require regular lubrication to maintain performance and avoid premature wear.

Ultimately, selecting bushings or bearings depends on the specific needs of your system. For heavy loads at slower speeds, bushings are an excellent choice. For speed, precision, and minimal friction, bearings are better suited.

Environmental Conditions and their Impact on Bushing Performance

The performance and lifespan of a bushing can be significantly influenced by environmental factors such as temperature extremes, humidity, exposure to chemicals, and abrasive contaminants. For example, bushings used in mining or agriculture may encounter constant exposure to dirt and moisture, requiring sealed or self-lubricating designs. In contrast, applications in cleanrooms or food processing environments demand non-contaminating, hygienic materials like PTFE or stainless steel. Choosing the right bushing for specific conditions ensures reliable operation and reduces the risk of premature failure.

What are the bushings on a car?

Bushings serve an indispensable role in vehicle suspension systems. These small components, commonly referred to as bushings car in automotive contexts, connect suspension components like control arms or stabilizer bars to the chassis. They help absorb shocks, reduce noise, and enable smooth movement.

Key Functions of Automotive Bushings:

- Shock Absorption: Bushings absorb road vibrations, ensuring a smoother and more comfortable ride.

- Flexibility: They allow suspension components to move freely without transmitting excessive force to the chassis.

- Noise Reduction: By minimizing vibrations, bushings reduce noise inside the vehicle.

Signs of Worn in Automotive Bushings

Monitoring the condition of your bushings can prevent further damage to the vehicle’s suspension system. Common signs of excessive wear include unusual noises such as clunking or squeaking, especially when driving over bumps or turning. You might also notice increased vibration through the steering wheel or reduced handling performance. Timely inspection and replacement are key to maintaining ride quality and vehicle safety.

Automotive bushings are commonly made from rubber for flexibility or metal for durability. The material choice depends on the performance requirements, with rubber offering better comfort and metal delivering greater strength.

OEM vs. Aftermarket Bushings

When replacing bushings, users often face a choice between original equipment manufacturer (OEM) components and aftermarket alternatives. OEM bushings are designed to match factory specifications, ensuring consistent performance. Aftermarket options in contrast may offer performance enhancements, material upgrades, or cost savings. However, quality can vary widely among aftermarket brands, making it essential to choose reputable suppliers. For critical systems like suspension or power transmission, selecting the right supplier can significantly impact safety and reliability.

What are bushings in a transformer?

Beyond automotive and mechanical systems, bushings also play a vital role in electrical applications, particularly in transformers. Transformer bushings enable electrical conductors to pass safely through grounded barriers such as the walls of a transformer, while maintaining insulation.

Functions of Transformer Bushings:

- Electrical Insulation: Bushings insulate electrical conductors, preventing short circuits and ensuring safety.

- Mechanical Support: They provide stability for conductors transitioning through barriers.

- Heat Dissipation: High-quality materials used in transformer bushings aid in cooling and heat management in electrical systems.

Types of Transformer Bushings

Transformer bushings can be broadly classified into oil-impregnated paper (OIP) and resin-impregnated paper (RIP) bushings. OIP bushings are immersed in insulating oil and are known for their excellent dielectric properties. However, they require regular monitoring to avoid leakage. In contrast, RIP bushings use resin as an insulator and are more environmentally friendly due to their dry-type construction. Each type offers distinct advantages depending on the installation and maintenance requirements.

Materials like porcelain and composite polymers are often used for transformer bushings due to their insulating properties and durability. Regular inspections are crucial to maintain the efficiency and safety of these critical components.

Are bushings bronze or brass?

The material composition of bushings is a key factor in their performance. Two common materials are bronze and brass, each offering unique benefits:

Bronze Bushings:

- Known for their strength, durability, and wear resistance.

- Ideal for heavy-duty applications for handling high loads and strenuous conditions.

Brass Bushings:

- Easier to machine, making them suitable for precision applications.

- Excellent corrosion resistance, making them effective in marine or water-related environments.

- Softer than bronze, which may make them less durable in certain setups.

How to Choose the Right Bushing Material

When selecting a bushing material, consider factors such as operating temperature, exposure to chemicals, load capacity, and lubrication availability. For instance, polymer bushings are excellent in corrosive environments, while sintered bronze bushings perform well under high loads with intermittent motion. Consulting a material compatibility chart or supplier guide can help ensure the longevity and effectiveness of the bushing in your application.

The choice between bronze and brass depends on your specific needs, but both materials deliver the durability and reliability of metal bushings.

What do stiffer bushings do?

The stiffness of a bushing directly influences its performance, especially in automotive and mechanical systems.

Benefits of Stiffer Bushings:

- Improved Control:

- Stiffer bushings reduce excessive movement, enhancing stability and handling.

- Enhanced Precision:

- They maintain alignment more effectively, which is crucial for performance-driven applications.

- Durability:

- Stiffer materials resist compression, extending the lifespan of the component.

However, there’s a trade-off. Stiffer bushings may increase noise and vibrations, making them less suitable for applications prioritizing comfort.

Should I get hard or soft bushings?

When replacing bushings, it’s essential to consider whether hard or soft options are best for your situation.

Hard Bushings:

- Offer higher durability and better control for performance-focused or heavy-duty systems.

- Limit flexibility, which prioritizes precision over comfort.

Soft Bushings:

- Provide a quieter, more comfortable experience by reducing vibrations and noise.

- They are more flexible, making them ideal for less demanding applications.

Custom Bushings and Performance Tuning

In performance applications—like motorsports or specialized machinery—custom bushings are often engineered to meet specific tolerances and stiffness ratings. These bushings can be tailored using CNC machining and advanced materials to achieve the perfect balance between rigidity and compliance. Tuned bushings enhance the dynamics of a system, offering a competitive edge in both precision and durability.

Noise, Vibration, and Harshness (NVH) in Bushing Design

Engineers often consider NVH characteristics when designing or selecting bushings. In automotive and industrial machinery, soft or elastomeric bushings help dampen vibrations and reduce transmitted noise. However, in high-performance setups, stiffer bushings may be chosen to improve handling or precision, accepting slightly increased noise levels as a trade-off. Balancing NVH considerations with performance requirements is essential for achieving an optimal user experience, especially in consumer-facing products.

Are Bushings Expensive to Replace?

The cost of replacing bushings depends on several factors, including the type of bushing, its material, and labor expenses. When considering bushings metal price, it’s important to weigh durability against upfront cost.

- Metal Bushings tend to be more expensive due to material costs, but typically offer a longer lifespan.

- Rubber Bushings are more affordable but may wear out faster, requiring more frequent replacements.

- Labor Costs can add up, as replacing bushings often involves disassembling adjacent components.

While bushing replacement costs can vary, ensuring your bushings are in good condition helps maintain system longevity and prevent more significant, costly damage.

Future Trends in Bushing Technology

As industries evolve, so does bushing technology. Emerging trends include smart bushings equipped with sensors that monitor vibration, load, and temperature in real-time. These intelligent components enable predictive maintenance, reducing downtime and extending equipment life. Additionally, sustainability is becoming a key consideration, with manufacturers exploring biodegradable materials and eco-friendly production processes to meet environmental regulations.

Installation Techniques and Best Practices

Proper installation is crucial to ensuring that bushings perform as intended. Common methods include press-fitting, bonding with adhesives, or using flanged designs that are easier to align and secure. Improper installation can lead to premature wear, misalignment, or even structural damage. Always follow the manufacturer’s guidelines, including recommended tolerances, lubrication requirements, and tool selection, to achieve a secure and lasting fit. Technicians should also inspect the housing and shaft for wear or scoring before inserting a new bushing.

Bushing Lifecycle and Replacement Guidelines

Understanding the expected life cycle of a bushing helps in planning maintenance schedules and avoiding unexpected breakdowns. Most bushings are rated based on operational hours or load cycles, which can vary depending on material, usage conditions, and installation quality. Regular inspections for signs of cracking, deformation, or unusual movement are essential.

Some industries implement condition-based monitoring systems to detect wear trends over time. Replacing bushings proactively—rather than reactively—helps maintain system efficiency, reduces downtime, and prevents damage to adjacent components. Establishing replacement intervals based on manufacturer specifications or field data is a best practice for long-term equipment reliability.

Conclusion

Bushings are unsung heroes in countless systems, balancing functionality and durability while providing cost-effective solutions. From reducing noise and vibrations in vehicles to offering insulation and stability in transformers, these components are indispensable in countless applications. Understanding the nuances of bushings – from materials like bronze and brass, to choosing between hard and soft options – is key to optimizing performance and extending the life of your systems. Investing in the right bushing ensures long-term performance, safety, and reliability.

For further insights or assistance with selecting the right bushings for your needs, reach out to SC Industries to explore tailored solutions for your applications.

Bushing Material for Steel Shaft

Comments Off on Bushing Material for Steel Shaft

What is the purpose of a bushing sleeve?

A bushing sleeve is a key component in many mechanical systems, providing a low-friction interface between the shaft and its housing. It mitigates wear and tear, extending the lifespan of machinery while ensuring smooth operation. By acting as a protective layer, bushings help sustain the integrity of more critical and costly structural components.

Beyond reducing friction, bushing sleeves dampen vibrations, align moving parts, and manage misalignments. Their ease of replacement compared to the machinery itself makes them an essential part of sustainable equipment maintenance.

Common applications of bushings for steel shafts include automotive engines, industrial machinery, and agricultural machines. For instance:

- For high-temperature environments, bearing bushes made of bronze or composites thrive due to their excellent heat resistance, durability, and ability to handle heavy loads without strain. They are ideal for industrial machinery, automotive applications, and other demanding settings.

- Polymer bushings work well in less demanding, cost-sensitive applications. These bushings are lightweight, corrosion-resistant, and require little to no lubrication, making them suitable for household appliances, office equipment, and applications where cost efficiency is a priority.

- They are designed for industries demanding exceptional durability and strength – such as construction, mining, automotive, and heavy machinery – where dependable performance under extreme stress is essential.

- High-performance bushings for metal applications deliver superior wear resistance, minimize friction, and guarantee a longer lifespan compared to traditional bushings, which are prone to failure under heavy loads or harsh operating conditions.

Click on Steel Bushing to delve deeper into their applications and gain a comprehensive understanding of their uses.

What is the function of a shaft sleeve?

A shaft sleeve is a protective device used to shield shafts from abrasion, corrosion, and other forms of degradation caused by operational friction. Typically mounted onto the shaft, it ensures that the inner components of the machinery remain intact, even in challenging conditions.

The function of a shaft sleeve aligns closely with the operation and efficiency of the steel bushing that surrounds it. Together, these systems reduce heat generation and prevent metal-to-metal contact, addressing operational safety and longevity concerns.

The primary functions of shaft sleeves include:

- Protecting the shaft from wear due to environmental conditions: This involves shielding the shaft from exposure to elements such as dust, moisture, and debris – which can cause corrosion, abrasion, or degradation over time. Proper protection helps extend the lifespan of the shaft and ensures reliable machine performance.

- Enabling smoother rotation by maintaining proper alignment: By keeping the shaft properly aligned with other components, smoother rotation is achieved, reducing friction and wear. This enhances efficiency, minimizes energy consumption, and decreases the risk of mechanical failure.

- Accommodating thermal expansion without affecting the core machinery: As machinery operates, components like shafts can expand or contract due to temperature changes. Proper design and materials allow the shaft to accommodate thermal expansion without causing misalignment, stress, or damage to the surrounding machinery, ensuring consistent and reliable operation.

By using bushings for steel shafts, manufacturers can ensure the long-term durability of the shaft sleeve, particularly in environments requiring high abrasion resistance.

What materials are used for bushing?

Multiple materials are used to manufacture bushings to ensure their suitability for a range of applications. Selection depends on factors like load capacity, friction reduction, resistance to wear, thermal conductivity, and chemical stability. Below are common materials used to make bushing sleeves:

- Bronze:

- Ideal for high-load applications.

- Provides excellent wear resistance and good thermal conductivity.

- Common in industrial and automotive bushings.

- Plastic:

- Lightweight and cost-effective.

- Usually made from plastic bushing materials like PTFE, nylon, or UHMWPE.

- Best for applications needing low noise and low-friction motion.

- High strength and load-bearing capacity.

- Used in extreme conditions requiring durability.

- Often combined with top coatings or liners for better performance.

- Composite Materials:

- Reinforced metals, ceramics, or polymers with fibers.

- Useful for industries seeking high performance with low maintenance.

- Other Types of Bushing Materials:

- Include alloys like brass for more specific use cases.

- Advanced materials incorporating ceramics for extreme wear resistance.

| Bushing Material Type | Description | Common Applications |

| Composite Materials | Reinforced metals, ceramics, or polymers with fibers | Industries seeking high performance with low maintenance |

| Alloys (e.g., Brass) | Specific alloys tailored for particular use cases | Applications requiring enhanced durability and unique properties |

| Advanced Ceramic Materials | Materials incorporating ceramics for extreme wear resistance | Extreme conditions require superior wear and temperature resistance |

| High-Strength Steel | Engineered for high strength and load-bearing capacity, often paired with coatings or liners for better performance | Extreme conditions require durability and load resilience |

Selecting the right bushing material can help address specific mechanical or operational challenges. For instance:

- For high-temperature environments, bearing bushes made of bronze or composites thrive.

- Polymer bushings work well in less demanding, cost-sensitive applications.

When choosing a bushing material, it’s essential to consider factors like friction, wear resistance, and maintenance requirements. For applications requiring self-lubrication, polymer bushings are an excellent option, reducing the need for regular lubrication while offering quiet operation. Metal-polymer composite bushings combine the strength of metals with the low-friction properties of polymers, making them ideal for high-load, low-speed applications. Ceramic bushings are increasingly being used in industries where electrical insulation, high corrosion resistance, and low thermal expansion are critical. Each type of bushing material brings distinct advantages, making it crucial to analyze the operational environment and specific application needs before making a selection.

What is the best material for bushings?

The best bushing material depends on individual application requirements such as load, speed, environment, and budget. Here’s a detailed comparison of the top options:

| Type of Bushing | Key Features | Best For |

| Bronze Bushings | High-load, high-speed applications, excellent wear resistance | Industrial machines, automotive components |

| Steel Bushings | Extraordinary strength, often coated to reduce friction | Heavy-duty equipment, steering mechanisms |

| Polymer Bushings | Water and chemical resistance, lightweight, quieter than metal | Household appliances, medical devices |

| Aluminum Bushings | Lightweight, excellent corrosion resistance | Low-load applications |

The best bushing material for steel shafts often depends on the application’s load, motion, and environmental conditions. For heavy, high-velocity shafts, bronze bushings or composite materials with steel shells are often considered the best option. Due to its strength and durability, bronze also features a high load-carrying capacity, enhancing performance and longevity.

For applications involving high speeds or frequent motion, the self-lubricating properties of PTFE bushings enable them to reduce friction and wear, enhancing efficiency. Additionally, the operating environment significantly impacts material choice. For example, aluminum bushings are ideal in environments with minimal exposure to moisture or chemicals, while composite or polymer bushings are better suited for corrosive or wet conditions due to their resistance to rust or chemical reactions.

Where heat is a concern, high-temperature-resistant materials such as graphite-impregnated bushings can prevent deformation and maintain performance under elevated thermal conditions.

Selecting the correct bushing material ensures optimal functionality, extends the lifetime of the shaft, and minimizes maintenance requirements.

What is the strongest bushing material?

The strongest bushing material – one that ensures durability, strength, and excellent performance in extreme conditions – is hardened steel. This material is specifically designed to handle maximum load-bearing applications, maintaining structural integrity under stress.

Key Benefits of Hardened Steel Bushings:

- Strength:

- Delivers exceptional stress resistance, guaranteeing durability and reliable performance even in the most demanding conditions.

- Efficiently manages heavy radial and axial loads, making it perfect for high-pressure applications while ensuring stability and optimal performance in challenging environments.

- Wear Resistance:

- Engineered for exceptional durability and performance, steel bushings deliver reliable operation even in the toughest environments, including dusty, abrasive, and harsh conditions. Built to resist wear and tear, they are perfectly suited for demanding applications.

- Applications:

- Perfect for industries requiring superior durability and strength, such as construction, mining, automotive, and heavy machinery sectors, where reliability under intense stress is critical.

- Commonly utilized in high-performance bushing applications, offering enhanced wear resistance, reduced friction, and extended lifespan compared to traditional bushings, which often fail under heavy loads or extreme operating conditions.

| Feature | Description | Benefits |

| High Wear Resistance | Designed to withstand significant friction and operational stress. | Improves longevity and reduces maintenance requirements. |

| Reduced Friction | Engineered to minimize friction between moving parts. | Enhances efficiency and lowers energy consumption in machinery. |

| Temperature Durability | Operates effectively across a wide range of temperatures, including extreme heat or cold. | Maintains performance and reliability in varying environmental conditions. |

| Heavy Load Capacity | Capable of handling substantial loads without strain or failure. | Ensures safer and more efficient functioning of heavy-duty equipment. |

| Low Maintenance | Requires minimal upkeep due to superior material properties. | Lowers operational costs and limits downtime for repairs or replacements. |

| Versatile Applications | Suitable for a variety of industries and uses, from automotive to mining operations. | Provides adaptable solutions tailored to specific industrial needs. |

Hardened steel bushings remain the gold standard for strength, but composite materials reinforced with ceramics are quickly proving to be formidable alternatives, especially in advanced, high-tech applications.

Does anyone make custom steel bushings?

Many manufacturers specialize in developing custom steel bushings tailored to unique application needs. These custom solutions are designed to ensure that the bushing for steel shafts meets specific dimensions, operational challenges, and performance requirements, providing a precise and reliable fit for a wide range of industries.

Key providers of custom steel bushings not only bring expertise but also offer a variety of specialized services, including:

- Design and engineering consultancy: Skilled experts collaborate closely with clients to develop bushings tailored to their unique applications. This process involves an in-depth analysis of the client’s needs, including performance requirements, operational conditions, and load dynamics. Through this partnership, the design process ensures optimal performance, extended durability, and cost efficiency, providing a solution that integrates seamlessly into the client’s machinery or systems.

- Advanced manufacturing processes: Cutting-edge manufacturing techniques such as co-extrusion, injection molding, and precision CNC machining are utilized to produce bushings with exact tolerances and exceptional quality. These processes ensure consistent results, reduce material waste, and enable the production of both standard and custom bushing designs.

Manufacturers also incorporate quality control measures at every stage, ensuring the final product meets or exceeds industry standards.

- Material optimization: Manufacturers guide clients in selecting the most suitable materials for their specific needs. Options include robust materials like steel for heavy-duty applications, corrosion-resistant bronze for high-temperature environments, or lightweight, low-friction polymer bushings for applications requiring reduced wear and noise. This careful material selection is based on factors such as operational requirements, environmental conditions (such as exposure to moisture or chemicals), load capacities, and expected life cycle, ensuring maximum reliability and performance.

These custom steel bushings are widely used across industries such as automotive, agricultural, and aerospace. For example, in the automotive sector, they help improve vehicle efficiency and reduce wear, while in aerospace, they ensure high performance under extreme conditions.

Companies like GGB Bearing Technology and others excel in delivering tailored solutions for a diverse range of types of bushings, addressing complex challenges with innovation and precision.

If you’re looking for high-quality custom bushings, partnering with a provider who offers end-to-end design to manufacturing support can make all the difference in achieving long-term success for your applications.

Additional Insights on Bushings

Types of Bushings in Transformer Applications

Transformer bushings typically use materials such as porcelain or epoxy resin for electrical insulation:

- Porcelain bushings are rigid and stable over time.

- Composite bushings provide better mechanical and thermal performance.

Conclusion

Selecting the right bushing material for a steel shaft is essential to ensuring that machinery performs reliably and efficiently. Whether it’s bronze bushings, steel, or advanced composites, the material must be carefully matched to the specific demands of the application.

Among these options, steel bushings stand out as a top choice for heavy-duty, high-stress environments, offering exceptional strength, durability, and versatility. For tailored solutions that meet your exact requirements, consider working with manufacturers specializing in custom steel bushings designed to align perfectly with your business needs.

Contact SC Industries today to learn how our expertise in custom steel bushings can help optimize your operations, reduce costly downtime, and boost your bottom line. Whether you need reliability, precision, or performance, our team is ready to deliver solutions that exceed expectations. Don’t wait—partner with us now to achieve unparalleled results!

Steel Bushing

Comments Off on Steel Bushing

Finding reliable, high-performance solutions is essential to meet the rigorous demands of modern manufacturing operations. Precision and durability are not just desirable traits; they are critical requirements for ensuring efficiency and long-lasting results. Custom components, such as metal bushings, play a vital role in achieving these goals. Crafted with advanced engineering, premium materials, and a deep understanding of industry needs, these solutions are designed not only to meet but often exceed expectations. By combining expertise with innovative design, manufacturers can ensure that their operations maintain peak performance and deliver exceptional results.

What are Steel Bushings in Manufacturing?

Bushings, also known as steel bushings or sleeves, are cylindrical components engineered to reduce friction, support moving parts, and prevent wear and tear in machinery. They function as an interface between mechanical parts, ensuring smoother motion and minimizing direct contact between surfaces.

Widely used in industrial machinery, automotive applications, and heavy equipment, steel bushings are known for their strength, durability, and resistance to wear under extreme conditions. Their robust construction makes them an ideal choice for applications that demand reliability and longevity.

These components come in various designs and materials, such as stainless steel bushings, bronze, or composite materials. For example, stainless steel sleeve bushings are often utilized in high-stress environments for their corrosion resistance and durability. The versatility of bushings allows them to be used in industries ranging from automotive to aerospace manufacturing.

Bushings also play a crucial role in extending the lifespan of machinery. They are commonly part of shafts, pivots, and bearings, offering a cost-effective solution for wear resistance. Whether you’re working on heavy-duty applications or precision machinery, custom metal bushings can be tailored to meet specific requirements.

What is a Steel Bushing?

A steel bushing is a cylindrical mechanical component made from steel that serves as a lining for a hole to reduce friction, absorb shock, or guide moving parts. Steel bushings are commonly used in machinery and industrial applications where metal components must slide or rotate against one another. Their robust construction allows them to endure high pressure, heavy loads, and extreme temperatures.

Steel bushings act as protective sleeves between two parts, preventing direct contact and minimizing wear. They are frequently used in automotive systems, construction equipment, and industrial machinery. Thanks to steel’s durability, these bushings maintain structural integrity in harsh environments, offering a cost-effective and long-lasting solution.

These components are available in various forms—such as sleeve, flanged, or thrust bushings, depending on the specific requirements of the application. Their high load-bearing capacity and corrosion resistance make them essential in systems that require precision, reliability, and longevity.

What is the Main Purpose of a Bushing?

The primary purpose of a bushing is to act as a protective layer, reducing friction and wear in a system. Bushings serve as a barrier between mechanical parts, allowing smooth motion while protecting the components from wear and tear.

Key purposes include:

- Minimizing Friction: Bushings reduce friction between the moving and stationary parts of a machine.

- Extending Equipment Lifespan: By absorbing wear, bushings prevent costly damage to parts.

- Providing Alignment: Certain designs, such as stainless steel flanged bushings, help align rotating components.

- Improved Performance: Bushings enhance performance by ensuring machinery runs smoothly, even under extreme conditions.

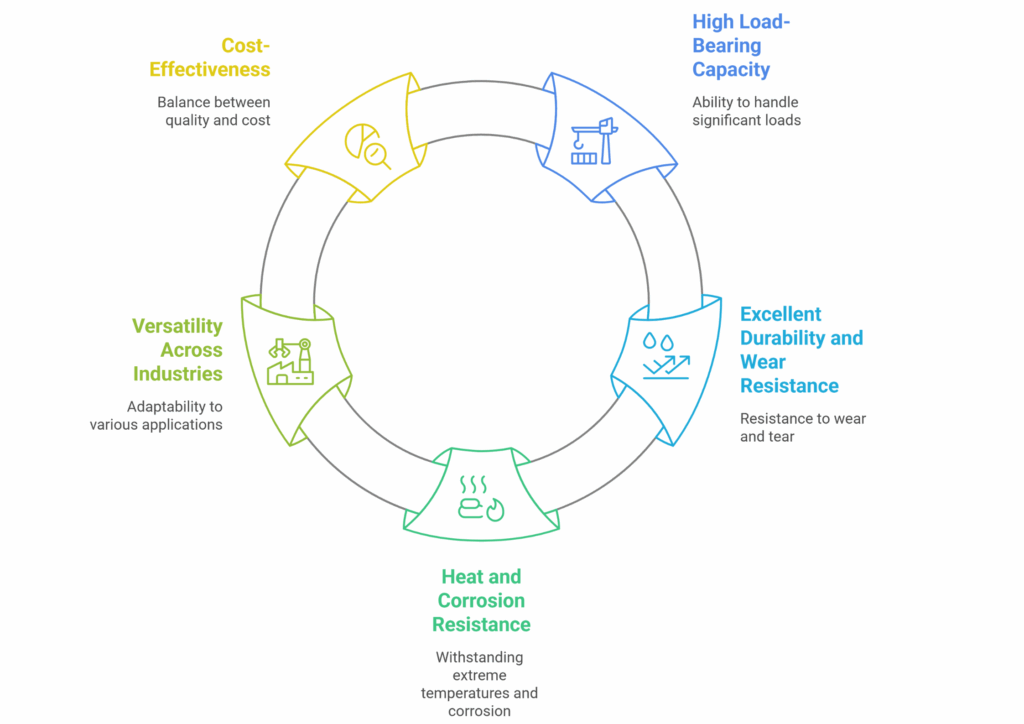

Characteristics of Steel Bushings

Steel bushings are known for their exceptional qualities, making them a preferred choice for a wide range of industrial applications. Below are the key characteristics that set steel bushings apart:

- High Load-Bearing Capacity: Steel bushings are engineered to handle significant loads, making them ideal for demanding environments. Whether supporting heavy machinery or managing the stress of high-speed operations, their robust construction ensures reliable performance under intense pressure.

- Excellent Durability and Wear Resistance: Designed to endure harsh conditions, steel bushings boast outstanding resistance to wear and tear. Their ability to maintain structural integrity even in environments with high friction or exposure to abrasive elements makes them a reliable choice for long-term use.

- Heat and Corrosion Resistance: Many steel bushings are treated or coated to withstand extreme temperatures and resist corrosion. This feature ensures longevity, even in applications where exposure to heat, moisture, or chemicals is a concern.

- Versatility Across Industries: One of the standout benefits of steel bushings is their ability to adapt to various applications. From automotive engines and industrial machinery to aerospace systems and construction equipment, steel bushings provide the strength and reliability these demanding sectors require. Their ability to meet diverse operational needs highlights their widespread applicability.

- Cost-Effectiveness: Steel bushings strike an excellent balance between quality and cost. Their long lifespan reduces the need for frequent replacements, translating into lower maintenance costs and increased productivity over time.

- Customizable Design Options: Steel bushings can be customized to meet specific requirements, including size, shape, and material composition. This flexibility allows manufacturers to tailor bushings for specialized applications, ensuring optimal performance.

Types of Steel Bushings

Steel bushings come in a variety of types, each suited for specific applications and conditions. Below are some commonly used bushing types:

- Plain Bushings: These are the simplest type, designed for applications with low-speed motion and minimal load requirements.

- Flanged Bushings: Featuring an integrated flange, these bushings provide added support for axial loads and help with proper alignment.

- Sleeve Bushings: Also known as cylindrical bushings, they are ideal for handling radial loads and are widely used in various machines.

- Thrust Bushings: Designed to manage axial loads, these bushings are often employed in applications like automotive steering systems.

- Flexible Bushings: These bushings offer a degree of flexibility and are commonly used to dampen vibrations and reduce noise.

- Flanged Bushings: Flanged bushings are similar to sleeve bushings but feature an additional flange at one end. This flange helps to position the bushing and prevent axial movement, making them ideal for applications where stability is critical, such as conveyor systems or automotive assemblies.

- Spherical Bushings: These bushings are designed to handle both angular misalignment and radial loads. With an internal spherical shape, they are often used in heavy machinery, aircraft, and other equipment requiring high levels of precision and flexibility.

- Metal-Polymer Composite Bushings: Constructed from a combination of metal and polymer, these bushings offer good wear resistance and low friction. They are commonly utilized in applications where lubrication is limited or not feasible, such as in electric motors and agricultural equipment.

Each type of bushing is carefully engineered to serve specific purposes, ensuring optimal performance and longevity for the equipment in which they are employed. Choosing the right bushing type is crucial for achieving efficiency and reliability in various mechanical systems.

Factors to consider when selecting a steel bushing include the material composition, load capacity, operating temperature, and lubrication requirements. Steel bushings are often reinforced or alloyed with other materials to enhance their wear resistance and overall performance. Proper lubrication is critical to minimize friction and prevent wear, especially in high-speed or heavy-load environments. Additionally, it is important to evaluate the operating conditions and environmental factors, such as exposure to moisture or corrosive substances, to ensure the bushing can maintain durability over time. By carefully assessing these factors, users can optimize the efficiency and reliability of their machinery.

Common Applications of Steel Bushings:

Steel bushings are widely used in various industries due to their robust properties. For instance:

- Automotive Industry: They are essential in suspension systems, shock absorbers, and steering components to ensure stability and smooth operation.

- Construction Equipment: Steel bushings are used in heavy machinery like excavators, cranes, and loaders, where they endure heavy loads and continuous use.

- Aerospace and Defense: Their reliability and precision are critical in aircraft engines, landing gear systems, and defense machinery.

- Industrial Machinery: Steel bushings enhance the efficiency and longevity of conveyors, pumps, and gearboxes in manufacturing plants.

This versatility highlights their importance in ensuring the seamless operation and reliability of mechanical systems.

Whether taking the form of a stainless steel flanged bushing or a steel bushing sleeve, these components are engineered to perform under rigorous conditions, offering reliability and long service life.

| Application | Role of Steel Bushings | Benefits |

| Automotive Suspension Systems | Provide durable connections and reduce wear | Improved performance and reduced noise |

| Connecting Rods | Facilitate smooth motion between components | Increased efficiency and longevity |

| Transmission Components | Ensure seamless gear shifting | Enhanced reliability and durability |

| Construction Equipment | Withstand extreme stress and harsh environments | Prolonged equipment lifespan |

| Agricultural Tools | Sustains heavy usage and resists wear in tough conditions | Optimized functionality and lower downtime |

| Industrial Machinery | Minimize wear on moving parts and enable smooth operation | Enhanced productivity and reduced repairs |

Benefits of Using Steel Bushings

Steel bushings provide numerous advantages, making them a preferred choice in demanding applications. Their high strength and resilience allow them to withstand extreme pressures and heavy loads, ensuring long-lasting performance. Additionally, steel bushings offer excellent resistance to corrosion and abrasion, particularly when treated or coated with protective finishes such as zinc plating or anodizing. This resistance enhances their lifespan, even in harsh environments involving moisture, chemicals, or high temperatures. Steel bushings are also cost-effective due to their durability and lower maintenance requirements, reducing downtime and replacement costs over time.

When choosing components for demanding applications, steel bushings offer several key advantages:

- High Durability – Steel bushings are designed to withstand intense pressure, high temperatures, and heavy loads without compromising performance.

- Reduced Friction – With proper lubrication, they deliver smooth, efficient motion, minimizing wear and tear on both the bushing and the surrounding parts.

- Corrosion Resistance – Many steel bushings are treated or coated to resist corrosion and extend their lifespan even in harsh environments.

- Customizability – Manufacturers such as SC Industries can produce steel bushings tailored to specific dimensions, tolerances, and requirements, ensuring a perfect fit for any application.

- Cost-Effectiveness – Despite their durability and robust performance, steel bushings are a cost-effective solution for many industries. Their long lifespan and minimal maintenance requirements lower overall operational costs, making them a practical choice for a wide range of applications.

- Versatility – Steel bushings can be utilized in many industries, including automotive, construction, aerospace, and manufacturing. Their adaptability ensures they can meet the demands of various functions and operating conditions.

| Advantage | Benefit |

| Durability | Steel bushings are designed to withstand high levels of stress, making them ideal for heavy-duty applications. |

| Cost-Effectiveness | Their long service life and low maintenance needs reduce overall expenses for companies. |

| Resistance | Exhibiting excellent resistance to wear, corrosion, and extreme temperatures, steel bushings perform well in tough environments. |

| Versatility | Suitable for industries like automotive, aerospace, and construction, steel bushings adapt to a variety of operational requirements. |

| Environmental Impact | Many steel bushings are recyclable, contributing to sustainable practices in industrial applications. |

By leveraging these advantages, steel bushings continue to be a reliable and enduring component in countless mechanical systems worldwide. Their excellent performance and customizable features make them a preferred choice across multiple industries. Steel bushings play a critical role in ensuring that equipment maintains peak performance over time. Whether you’re looking for a standard solution or a custom design, steel bushings offer unmatched dependability for a diverse range of industrial needs.

Why Use a Bushing Instead of a Bearing?

While both bushings and bearings serve similar purposes, the choice between them often depends on the application. The use of bushings or ball bearings is a common decision point when selecting for a machine.

Key Differences Between Bushings and Bearings

Bushings are typically simpler in design compared to ball bearings, offering a cost-effective and low-maintenance solution for many applications. They are well-suited for environments where high loads and low rotational speeds are common, as they provide excellent load-carrying capabilities and wear resistance. Additionally, bushings operate quietly and are less sensitive to contamination, making them ideal for harsh conditions.

In contrast, ball bearings are designed for applications requiring precise motion and high-speed performance. They offer lower friction and are more efficient in reducing energy loss during operation. However, ball bearings are often more expensive and may require more maintenance to ensure longevity – especially in environments exposed to dirt or debris.

Bushings and bearings differ in several fundamental aspects, making each suitable for specific applications. Bushings, also known as plain bearings, are cylindrical components that provide a sliding motion between two surfaces. They typically operate without the need for rolling elements and can endure higher loads but tend to have lower speed limits compared to ball or roller bearings.

In contrast, ball bearings utilize rolling elements (balls) to reduce friction and support rotational motion. This design allows for higher speed capabilities and smoother operation, making ball bearings ideal for precision machinery and high-speed applications. However, they may require more maintenance and lubrication to function efficiently over time.

Understanding these differences allows engineers to choose a component that balances the trade-offs between durability, speed, load-bearing capacity, and ease of maintenance, ensuring optimal performance for the intended use.

The choice between a bushing and a bearing ultimately hinges on the specific requirements of the machinery and the operating conditions it will face.

| Feature | Ball Bearings | Alternative Components (e.g., Plain Bearings) |

| Motion Support | Rotational motion | Sliding motion |

| Speed Capability | Higher speeds due to reduced friction | Limited speed due to greater friction |

| Load-Bearing Capacity | Lower load tolerance | Higher load tolerance |

| Maintenance Requirements | Requires lubrication and maintenance | Often less maintenance-intensive |

| Suitability | Precision machinery, high-speed uses | Heavy-load, low-speed applications |

This table visually summarizes the key differences, helping to guide selection based on specific application needs.

Advantages of Bushings:

- Cost-Effectiveness: Bushings are generally more affordable and simpler to install than bearings.

- Versatility: Ideal for a wide range of applications, from shaft sleeve bushings in industrial settings to smaller systems in consumer products.

- Low Maintenance: Unlike ball bearings that may require lubrication, many bushings are self-lubricating.

- Shock Absorption: Bushings provide better damping capabilities in high-impact environments.

Limitations:

- Load and Speed: For high-speed or high-load applications, precision bearing bushing sleeves may be more suitable.

- Temperature Sensitivity: Certain bushing materials may not perform well under extreme temperatures, leading to deformation or a reduced lifespan. High temperatures can cause swelling or warping, while low temperatures might result in brittleness.

- Wear and Tear: Over time, bushings can experience wear, especially when used in applications with poor alignment or insufficient lubrication in non-self-lubricating types. This wear can lead to oscillation or vibration issues.

- Precision Limitations: Compared to bearings, bushings may lack the precision needed for applications requiring highly accurate rotational movement, making them unsuitable for some specialized machinery.

- Material Limitations: The performance of bushings can depend heavily on the material used. For example, plastic bushings may not provide the same strength or durability as metal ones in heavy-duty applications.

Bushings excel in applications where durability, vibration dampening, and cost considerations are critical.

Is a Bushing the Same as a Bearing?

No, a bush (short for bushing) and a bearing are not the same, although they share similar functions in reducing friction and facilitating motion. A bushing, such as a steel bushing sleeve, is a simple cylindrical component, whereas a bearing contains rolling elements (like balls or rollers) to support higher speeds and loads.

Key Differences:

- Design: Bushings are solid components, such as stainless steel sleeve bushings. Bearings contain movable parts and are designed for rotational precision.

- Applications: Bushings are used in moderate-speed and load settings. Bearings are preferred for high-speed, precision requirements.

- Maintenance: Many bushings are self-lubricating, while bearings often require ongoing lubrication.

Both components are essential in their respective fields, but steel bushings stand out for their simplicity, reliability, and cost-effectiveness.

What is the Best Material for Bushing?

The selection of bushing material depends on the specific application. Common materials include bronze, graphite composites, and stainless steel. Among these, stainless steel bushings are widely regarded as one of the best choices for demanding conditions.

Why Stainless Steel?

- Corrosion Resistance: Perfect for applications exposed to moisture or chemicals.

- High Strength: It withstands heavy loads without deforming.

- Durability: Long-lasting even in high-friction settings.

Applications of Stainless Steel Bushings

Stainless steel bushings excel in a variety of applications due to their superior properties. They are commonly used in industrial machinery, automotive components, and marine equipment, where their resistance to corrosion and durability ensures reliable performance. For example, in the automotive industry, stainless steel bushings are implemented in suspension systems and steering linkages to handle high stress and wear. Similarly, in marine environments, their resistance to saltwater corrosion makes them ideal for propeller shafts and other critical components. These qualities make stainless steel bushings a versatile and indispensable choice across multiple industries.