When it comes to industrial applications, Steel Bushings play a vital role in ensuring durability and the seamless operation of machinery. One question often asked is how the process of hardening improves bushings.

This blog will explore how bushings are hardened, why the process is necessary, and what factors influence the quality and performance of hardened steel sleeve bushings. By the end, you’ll have a clear understanding of why hardening is crucial and how it can enhance the lifespan of these essential components.

How Do You Harden Bushings?

Bushings, especially those made from steel, are subjected to various hardening processes to improve their durability and resistance to wear. But what does this involve? The hardening of bushings usually begins with the selection of the right grade of steel. Following this, the steel undergoes a heat treatment process that alters its physical and mechanical properties.

The heat treatment process typically involves:

- Heating: The bushing is exposed to a specific high temperature based on the type of steel used.

- Quenching: After heating, the bushing is rapidly cooled using a quenching medium like oil, water, or air.

- Tempering: To reduce brittleness and enhance toughness, the steel is reheated to a lower temperature and then cooled again.

These steps significantly strengthen the hardened steel sleeve bushings, ensuring they perform optimally under high stress and harsh operating conditions.

How Do You Harden Bearing Steel?

Bearing steel is most likely to be hardened after being formed and machined into the desired bearing shape and dimensions while it is still in a relatively soft (unhardened) state, making it easier to cut and shape precisely. The bearing components are subjected to heat treatment after they have been machined to near-final dimensions.

Here’s how it’s typically hardened:

- Carburization: This process adds carbon to the surface of the steel to improve its hardness and wear resistance.

- Induction Hardening: This method involves heating the surface of the bearing steel by electromagnetic induction, then quenching it rapidly. This creates a hardened exterior while maintaining a tough inner core.

- Cryogenic Treatment: Sometimes, the steel is cooled to sub-zero temperatures to relieve residual stress and enhance its structural integrity.

By following these steps, manufacturers ensure that bearing steel provides the longevity and reliability needed for crucial applications, such as used in Steel Bushing.

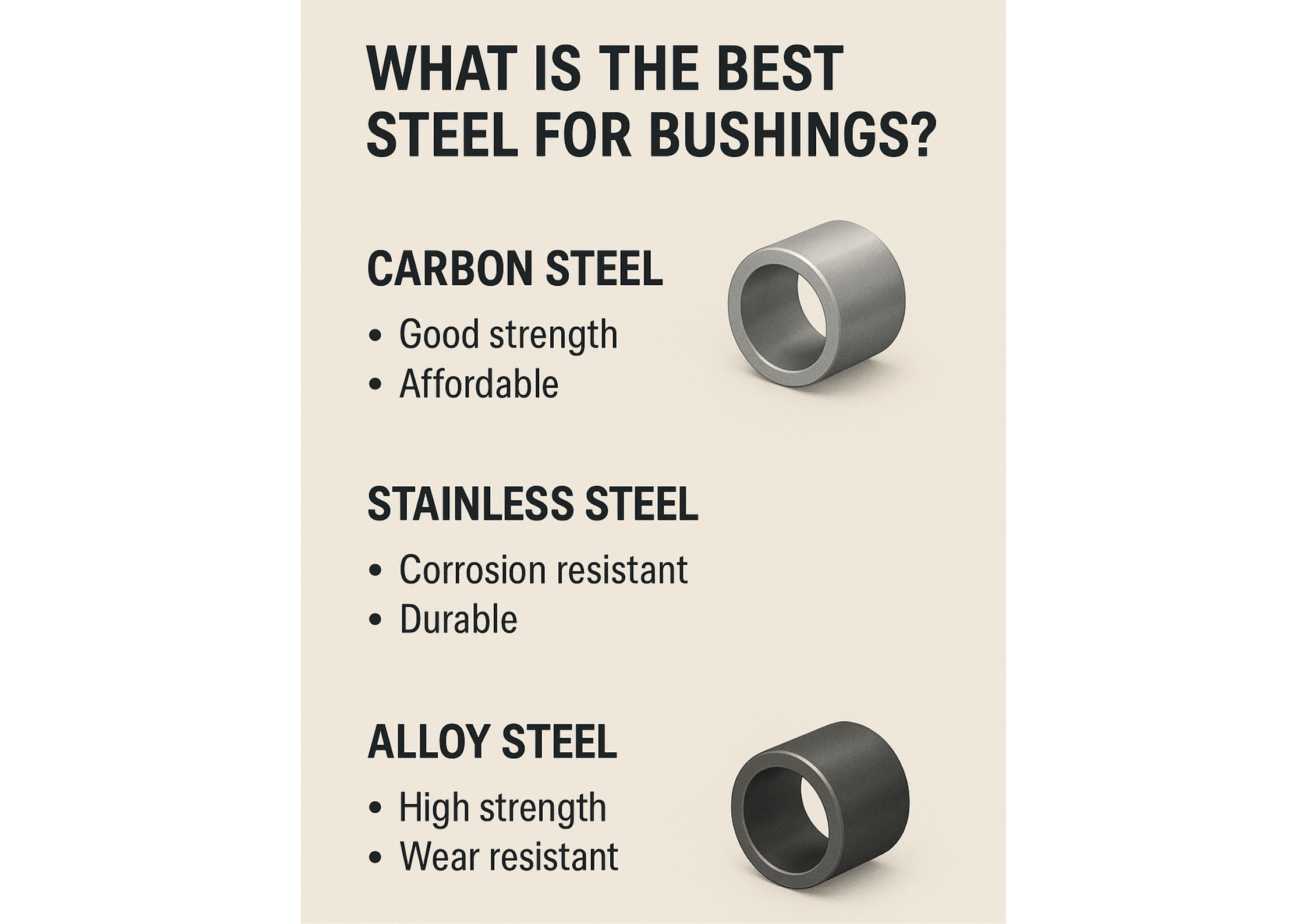

What Is the Best Steel for Bushings?

The choice of steel greatly influences a bushing’s performance and durability. Commonly used materials include:

- Carbon Steel: Known for its balance between strength and affordability, carbon steel works well for general applications.

- Stainless Steel: This is a preferred choice for environments prone to corrosion, offering both durability and rust resistance.

- Alloy Steel: With enhanced mechanical properties, alloy steel is ideal for high-stress, high-wear applications.

For the best results, many opt for hardened steel, particularly variants that have undergone meticulous heat treatments. Hardened steel sleeve bushings crafted from these materials can withstand extreme conditions, making them perfect for heavy-duty machinery in industrial settings.

What Is the Best Lubricant for Dry Bushings?

Lubrication is a critical factor in the performance of any bushing. For dry bushings – also known as self-lubricating bushings – the type of lubricant used must reduce friction and resist wear without requiring frequent re-application:

- Graphite-Based Lubricants: These are excellent for high-temperature applications as graphite can withstand heat while maintaining low friction levels.

- Oil-Impregnated Lubricants: A popular choice for dry bushings, these lubricants are infused into the bushing material itself, providing consistent lubrication over time.

- Molybdenum Disulfide: This is a solid lubricant suited for extreme pressure applications while offering prolonged protection.

When used in conjunction with Steel Bushing systems, the proper lubricant extends the life of the parts and ensures smoother operation. Selecting the right type also depends on the operational environment, so understanding needs is crucial for optimum performance.

Best Lubricant for Metal Bushings

While the above covers dry bushings specifically, it’s worth noting that for standard metal bushings, traditional lubricants such as high-performance oils and greases are often used. These products create a protective film between the bushing and its mating surface, reducing both friction and wear.

When selecting a lubricant, consider the following factors:

- Viscosity: Higher viscosity lubricants work better for heavy load applications.

- Temperature Tolerance: Ensure the lubricant can handle the thermal conditions of your application.

- Compatibility: Always check that the lubricant is chemical-compatible with the bushing material.

Conclusion

Hardening bushings through heat treatment processes like quenching, tempering, or carburization enhances their resistance to wear, extending their lifespan across various applications. From choosing the right steel type to understanding the lubrication needs of bushings, every step contributes to creating durable and reliable machinery components.

For industries relying on heavy-duty machinery, hardened steel sleeve bushings are a game-changer, offering unmatched longevity and performance. If your next project demands bushings that can withstand extreme wear and tear, consider exploring hardened steel options.

Explore our range of high-quality steel bushings specifically designed for industrial use. Contact our team today to learn more and find the ideal solution for your needs!