Hardened steel bushings are a crucial component in various mechanical systems, providing durability, precision, and reliability in industries ranging from automotive to heavy machinery. But what exactly is the material that makes these bushings so effective?

This article will explore the uses of steel bushings, what materials are ideal for high-performance applications, and why hardened bushings stand out as some of the toughest and most reliable components available.

What are steel bushings used for?

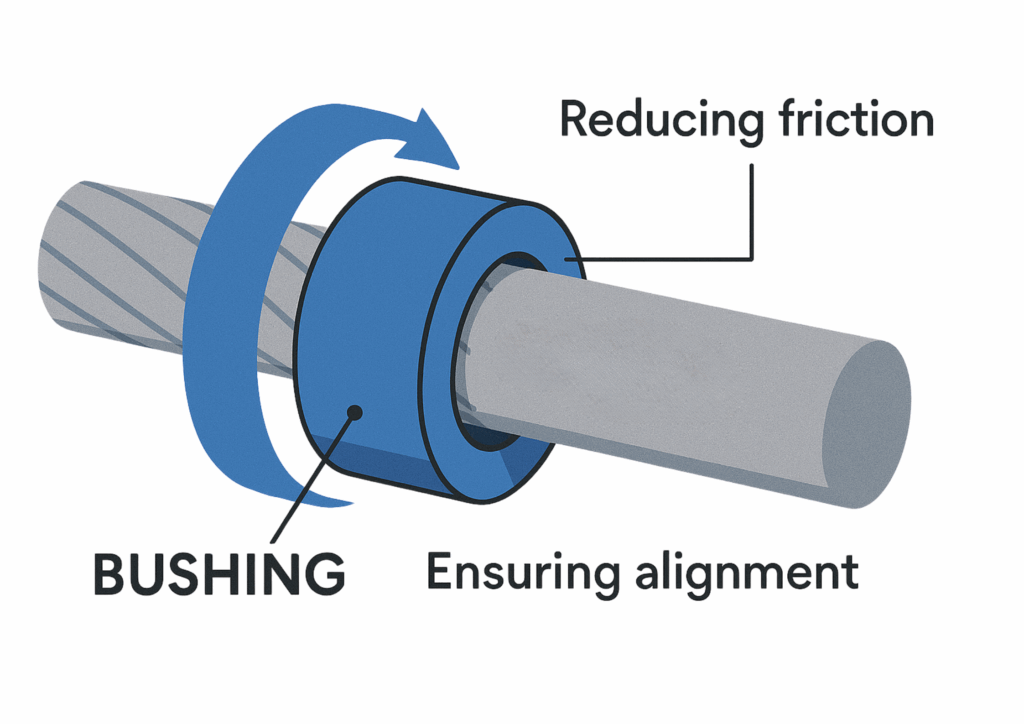

Steel bushings are mechanical components designed to reduce friction, absorb wear, and align moving parts in machinery. Often playing a vital role in high-stress environments, these bushings act as protective liners between parts with relative motion, mitigating wear caused by metal-to-metal contact.

Key applications of steel bushings include:

- Supporting rotating shafts in engines, motors, and pumps.

- Providing a durable interface in pivot points of heavy equipment like excavators or cranes.

- Enhancing precision in manufacturing equipment by minimizing vibration and misalignment.

Additionally, hardened steel sleeve bushings are frequently used in systems requiring exceptional wear resistance and reliability. Their hard exterior ensures long service life even under extreme loads or severe operating conditions.

What material is used for high-performance bushings?

The choice of material for high-performance bushings directly impacts their functionality, durability, and ability to withstand challenging conditions. Among the most preferred solutions is hardened steel bushes.

Hardened steel bushes are made of alloys that undergo specific heat treatments to strengthen their outer surface while preserving interior flexibility. The enhancements in hardness improve their ability to endure constant friction and repeated loads without deformation.

Other materials like bronze, brass, or composite polymers may also be used for bushings in less demanding applications. However, they cannot match the strength, wear resistance, or longevity of hardened steel sleeve bushings in high-performance settings.

What is the best material for steel bushings?

When considering the best material for steel bushings, several factors come into play, including strength, wear resistance, and load-handling capacity. For most demanding industries, steel bushing material treated with heat-hardening processes consistently outperforms other options.

Why hardened steel is ideal:

- Exceptional wear resistance: The hard outer layer minimizes wear and tear, even when exposed to abrasive conditions.

- High strength: It can endure substantial loads without deforming or cracking.

- Corrosion resistance: Certain types of hardened steel – such as stainless steel alloys – offer excellent resistance to rust or chemical damage.

Real-world example:

Heavy construction vehicles like bulldozers rely on hardened steel bushes for their pivot joints. These bushings allow smooth, repetitive joint movement while supporting the equipment’s weight and withstanding dirt, dust, and moisture.

The role of surface finish:

High-performance steel bushing material is often precision finished through processes like grinding and coating. This minimizes friction and further extends service life.

What type of steel is the hardest?

When it comes to identifying the hardest types of steel, it’s all about the manufacturing process. Hardened bushings are typically made from carbon or alloy steels that have undergone heat treatment to increase hardness. Here’s a closer look at what makes hardened steel stand out:

- Quenched and Tempered Steel:

This involves heating the metal to a high temperature, then rapidly cooling it in water or oil (quenching). The result? A significant boost in hardness and strength. - Tool Steel:

Often used for cutting tools and dies, this material boasts a unique balance of hardness and toughness. Its high carbon and alloy content makes it suitable for hardened bushings. - Martensitic Stainless Steel:

Known for its superior hardness, this type of steel combines the best of stainless and carbon properties, making it a strong contender for harsh environments.

Because of these treatments and material properties, hardened bushings offer unparalleled performance, even in severe operating conditions.

Conclusion

The right Steel bushing material can make or break the longevity and efficiency of mechanical systems. Hardened steel stands out for its toughness, wear resistance, and performance in demanding industries. Whether you’re supporting rotating shafts or protecting machinery from abrasion, investing in quality hardened steel sleeve bushings increases system reliability and longevity.

If you’d like to learn more about related products or applications, be sure to check out our comprehensive guide on Steel Bushing. For assistance with specific requirements about measurements, materials, or sizes feel free to contact us or explore our full catalog of metric hardened steel bushings.