When it comes to selecting the right bushing material, the options can seem overwhelming. From different materials to varied applications, knowing which bushing is appropriate for your needs is essential for performance and longevity.

Whether you’re working with a Steel Bushing, a bushing material for a steel shaft, or another type, understanding your options is key. This guide explores the most common types of bushings, materials, and the factors to consider when choosing the perfect fit.

How many types of bushings are there?

Bushings come in many forms, each tailored to specific applications. The following are the most common types you’ll encounter:

Steel Bushing Sleeve

A Steel Bushing Sleeve is one of the most common types, known for its durability and strength. These bushings are often used in construction, industrial machinery, and other heavy-duty applications. Steel offers a strong foundation that withstands high loads, making it ideal for environments with high friction and wear.

Bronze bushings

Bronze bushings provide excellent wear resistance due to their hardness and ability to withstand high temperatures. They are widely used in machines that demand consistent performance under extreme conditions. Their self-lubricating features, when combined with oil or grease, make them especially popular in automotive and manufacturing industries.

What are the different types of bushing materials

Bushings are manufactured using a wide array of materials, each offering unique benefits. Some of the most commonly used materials include:

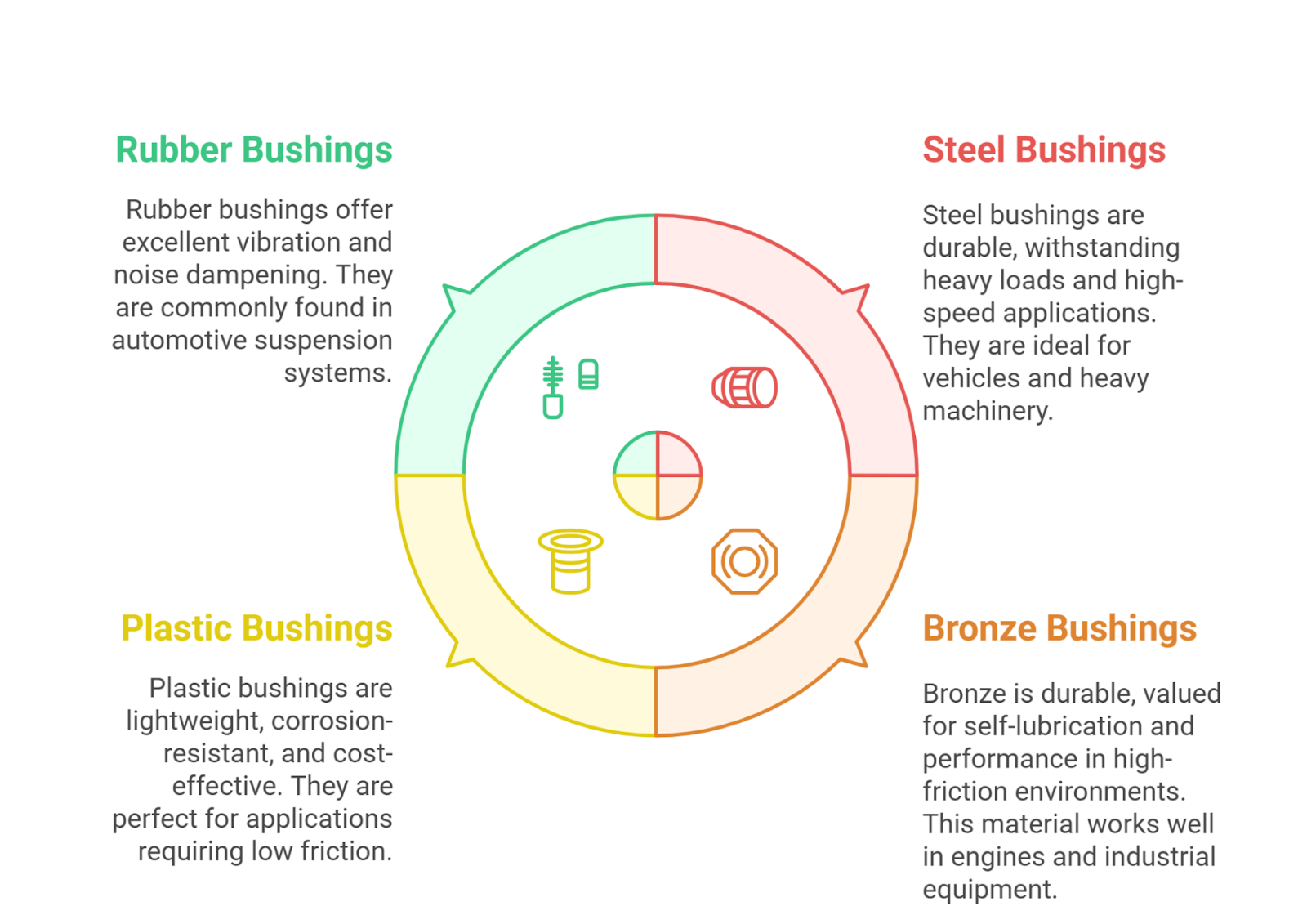

Steel

Steel bushings are highly durable, withstanding heavy loads and high-speed applications. They are ideal for use in vehicles, heavy machinery, and construction equipment, where reliability is paramount.

Bronze

Bronze is another highly durable material, valued for its self-lubricating abilities and performance in high-friction environments. This material works well in engines and industrial equipment.

Plastic

Plastic bushings are lightweight, corrosion-resistant, and cost-effective. While not as strong as steel or bronze, they are perfect for applications requiring low friction, such as household appliances or light machinery.

Rubber

Rubber bushings offer excellent vibration and noise dampening, commonly found in automotive suspension systems and industrial mounts.

Which material is best for bushings

Choosing the best material for a bushing largely depends on your specific use case. Here’s an in-depth look at the considerations involved:

What is the strongest bushing material for cars

When it comes to vehicles, the strongest bushing material is usually steel or bronze. Cars often demand bushings capable of withstanding high loads, friction, and temperature. Steel bushings excel in structural components like suspension systems, while bronze bushings are excellent in components like steering shafts where lubrication and smooth operation are vital.

Plastic bushing material for steel

A plastic bushing material for steel applications is a great choice when weight reduction, cost efficiency, or corrosion resistance is a priority. These bushings often contain composite or polymer materials that reduce friction and extend the service life of a steel shaft. Plastic bushings work well in environments where moisture exposure is a concern, as they resist rust and corrosion better than metal counterparts.

How do I choose bushing material

Choosing the right bushing material depends on several factors. Here’s what you should consider:

- Load and Stress

Assess the amount of load the bushing will support. Steel Bushing types are better for high-stress applications, while plastic works well for moderate loads. - Friction and Wear

For parts with constant motion, a self-lubricating material like bronze reduces wear and tear over time. - Environment

Consider the working environment. Is it exposed to moisture, high temperatures, or chemicals? Materials like plastic and rubber perform well in corrosive or extreme conditions, whereas steel offers strength and reliability. - Budget

While bronze bushings may be durable, they can also be costlier. For low-budget projects, plastic serves as a lightweight, economical alternative. - Lifespan

Choose materials suited to the desired longevity. Steel and bronze have longer lifespans, while rubber and plastic may require more frequent replacement.

Ultimately, your choice should align with the specifics of your project, carefully balancing performance, durability, and cost. Consider the level of performance required, the environmental conditions it will face, and your budget constraints to ensure you select the most suitable option for long-term success.

Selecting the right bushing material is crucial for achieving efficiency, durability, and cost-effectiveness in any application. Whether it’s a Steel Bushing, bushing material for steel shaft, or another type, understanding the differences in material strengths, weaknesses, and applications guides you towards the best choice.

If you’re unsure which bushing material suits your project, don’t hesitate to contact us for a consultation. For more on bushings and their uses, visit our Steel Bushing Guide.