Finding reliable, high-performance solutions is essential to meet the rigorous demands of modern manufacturing operations. Precision and durability are not just desirable traits; they are critical requirements for ensuring efficiency and long-lasting results. Custom components, such as metal bushings, play a vital role in achieving these goals. Crafted with advanced engineering, premium materials, and a deep understanding of industry needs, these solutions are designed not only to meet but often exceed expectations. By combining expertise with innovative design, manufacturers can ensure that their operations maintain peak performance and deliver exceptional results.

What are Steel Bushings in Manufacturing?

Bushings, also known as steel bushings or sleeves, are cylindrical components engineered to reduce friction, support moving parts, and prevent wear and tear in machinery. They function as an interface between mechanical parts, ensuring smoother motion and minimizing direct contact between surfaces.

Widely used in industrial machinery, automotive applications, and heavy equipment, steel bushings are known for their strength, durability, and resistance to wear under extreme conditions. Their robust construction makes them an ideal choice for applications that demand reliability and longevity.

These components come in various designs and materials, such as stainless steel bushings, bronze, or composite materials. For example, stainless steel sleeve bushings are often utilized in high-stress environments for their corrosion resistance and durability. The versatility of bushings allows them to be used in industries ranging from automotive to aerospace manufacturing.

Bushings also play a crucial role in extending the lifespan of machinery. They are commonly part of shafts, pivots, and bearings, offering a cost-effective solution for wear resistance. Whether you’re working on heavy-duty applications or precision machinery, custom metal bushings can be tailored to meet specific requirements.

What is a Steel Bushing?

A steel bushing is a cylindrical mechanical component made from steel that serves as a lining for a hole to reduce friction, absorb shock, or guide moving parts. Steel bushings are commonly used in machinery and industrial applications where metal components must slide or rotate against one another. Their robust construction allows them to endure high pressure, heavy loads, and extreme temperatures.

Steel bushings act as protective sleeves between two parts, preventing direct contact and minimizing wear. They are frequently used in automotive systems, construction equipment, and industrial machinery. Thanks to steel’s durability, these bushings maintain structural integrity in harsh environments, offering a cost-effective and long-lasting solution.

These components are available in various forms—such as sleeve, flanged, or thrust bushings, depending on the specific requirements of the application. Their high load-bearing capacity and corrosion resistance make them essential in systems that require precision, reliability, and longevity.

What is the Main Purpose of a Bushing?

The primary purpose of a bushing is to act as a protective layer, reducing friction and wear in a system. Bushings serve as a barrier between mechanical parts, allowing smooth motion while protecting the components from wear and tear.

Key purposes include:

- Minimizing Friction: Bushings reduce friction between the moving and stationary parts of a machine.

- Extending Equipment Lifespan: By absorbing wear, bushings prevent costly damage to parts.

- Providing Alignment: Certain designs, such as stainless steel flanged bushings, help align rotating components.

- Improved Performance: Bushings enhance performance by ensuring machinery runs smoothly, even under extreme conditions.

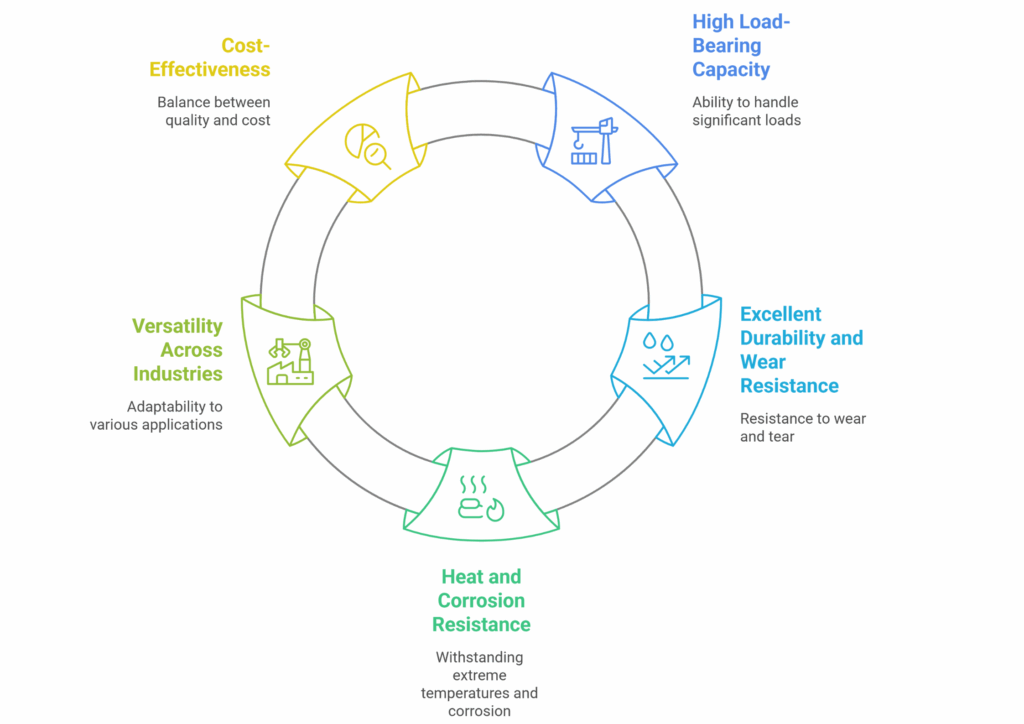

Characteristics of Steel Bushings

Steel bushings are known for their exceptional qualities, making them a preferred choice for a wide range of industrial applications. Below are the key characteristics that set steel bushings apart:

- High Load-Bearing Capacity: Steel bushings are engineered to handle significant loads, making them ideal for demanding environments. Whether supporting heavy machinery or managing the stress of high-speed operations, their robust construction ensures reliable performance under intense pressure.

- Excellent Durability and Wear Resistance: Designed to endure harsh conditions, steel bushings boast outstanding resistance to wear and tear. Their ability to maintain structural integrity even in environments with high friction or exposure to abrasive elements makes them a reliable choice for long-term use.

- Heat and Corrosion Resistance: Many steel bushings are treated or coated to withstand extreme temperatures and resist corrosion. This feature ensures longevity, even in applications where exposure to heat, moisture, or chemicals is a concern.

- Versatility Across Industries: One of the standout benefits of steel bushings is their ability to adapt to various applications. From automotive engines and industrial machinery to aerospace systems and construction equipment, steel bushings provide the strength and reliability these demanding sectors require. Their ability to meet diverse operational needs highlights their widespread applicability.

- Cost-Effectiveness: Steel bushings strike an excellent balance between quality and cost. Their long lifespan reduces the need for frequent replacements, translating into lower maintenance costs and increased productivity over time.

- Customizable Design Options: Steel bushings can be customized to meet specific requirements, including size, shape, and material composition. This flexibility allows manufacturers to tailor bushings for specialized applications, ensuring optimal performance.

Types of Steel Bushings

Steel bushings come in a variety of types, each suited for specific applications and conditions. Below are some commonly used bushing types:

- Plain Bushings: These are the simplest type, designed for applications with low-speed motion and minimal load requirements.

- Flanged Bushings: Featuring an integrated flange, these bushings provide added support for axial loads and help with proper alignment.

- Sleeve Bushings: Also known as cylindrical bushings, they are ideal for handling radial loads and are widely used in various machines.

- Thrust Bushings: Designed to manage axial loads, these bushings are often employed in applications like automotive steering systems.

- Flexible Bushings: These bushings offer a degree of flexibility and are commonly used to dampen vibrations and reduce noise.

- Flanged Bushings: Flanged bushings are similar to sleeve bushings but feature an additional flange at one end. This flange helps to position the bushing and prevent axial movement, making them ideal for applications where stability is critical, such as conveyor systems or automotive assemblies.

- Spherical Bushings: These bushings are designed to handle both angular misalignment and radial loads. With an internal spherical shape, they are often used in heavy machinery, aircraft, and other equipment requiring high levels of precision and flexibility.

- Metal-Polymer Composite Bushings: Constructed from a combination of metal and polymer, these bushings offer good wear resistance and low friction. They are commonly utilized in applications where lubrication is limited or not feasible, such as in electric motors and agricultural equipment.

Each type of bushing is carefully engineered to serve specific purposes, ensuring optimal performance and longevity for the equipment in which they are employed. Choosing the right bushing type is crucial for achieving efficiency and reliability in various mechanical systems.

Factors to consider when selecting a steel bushing include the material composition, load capacity, operating temperature, and lubrication requirements. Steel bushings are often reinforced or alloyed with other materials to enhance their wear resistance and overall performance. Proper lubrication is critical to minimize friction and prevent wear, especially in high-speed or heavy-load environments. Additionally, it is important to evaluate the operating conditions and environmental factors, such as exposure to moisture or corrosive substances, to ensure the bushing can maintain durability over time. By carefully assessing these factors, users can optimize the efficiency and reliability of their machinery.

Common Applications of Steel Bushings:

Steel bushings are widely used in various industries due to their robust properties. For instance:

- Automotive Industry: They are essential in suspension systems, shock absorbers, and steering components to ensure stability and smooth operation.

- Construction Equipment: Steel bushings are used in heavy machinery like excavators, cranes, and loaders, where they endure heavy loads and continuous use.

- Aerospace and Defense: Their reliability and precision are critical in aircraft engines, landing gear systems, and defense machinery.

- Industrial Machinery: Steel bushings enhance the efficiency and longevity of conveyors, pumps, and gearboxes in manufacturing plants.

This versatility highlights their importance in ensuring the seamless operation and reliability of mechanical systems.

Whether taking the form of a stainless steel flanged bushing or a steel bushing sleeve, these components are engineered to perform under rigorous conditions, offering reliability and long service life.

| Application | Role of Steel Bushings | Benefits |

| Automotive Suspension Systems | Provide durable connections and reduce wear | Improved performance and reduced noise |

| Connecting Rods | Facilitate smooth motion between components | Increased efficiency and longevity |

| Transmission Components | Ensure seamless gear shifting | Enhanced reliability and durability |

| Construction Equipment | Withstand extreme stress and harsh environments | Prolonged equipment lifespan |

| Agricultural Tools | Sustains heavy usage and resists wear in tough conditions | Optimized functionality and lower downtime |

| Industrial Machinery | Minimize wear on moving parts and enable smooth operation | Enhanced productivity and reduced repairs |

Benefits of Using Steel Bushings

Steel bushings provide numerous advantages, making them a preferred choice in demanding applications. Their high strength and resilience allow them to withstand extreme pressures and heavy loads, ensuring long-lasting performance. Additionally, steel bushings offer excellent resistance to corrosion and abrasion, particularly when treated or coated with protective finishes such as zinc plating or anodizing. This resistance enhances their lifespan, even in harsh environments involving moisture, chemicals, or high temperatures. Steel bushings are also cost-effective due to their durability and lower maintenance requirements, reducing downtime and replacement costs over time.

When choosing components for demanding applications, steel bushings offer several key advantages:

- High Durability – Steel bushings are designed to withstand intense pressure, high temperatures, and heavy loads without compromising performance.

- Reduced Friction – With proper lubrication, they deliver smooth, efficient motion, minimizing wear and tear on both the bushing and the surrounding parts.

- Corrosion Resistance – Many steel bushings are treated or coated to resist corrosion and extend their lifespan even in harsh environments.

- Customizability – Manufacturers such as SC Industries can produce steel bushings tailored to specific dimensions, tolerances, and requirements, ensuring a perfect fit for any application.

- Cost-Effectiveness – Despite their durability and robust performance, steel bushings are a cost-effective solution for many industries. Their long lifespan and minimal maintenance requirements lower overall operational costs, making them a practical choice for a wide range of applications.

- Versatility – Steel bushings can be utilized in many industries, including automotive, construction, aerospace, and manufacturing. Their adaptability ensures they can meet the demands of various functions and operating conditions.

| Advantage | Benefit |

| Durability | Steel bushings are designed to withstand high levels of stress, making them ideal for heavy-duty applications. |

| Cost-Effectiveness | Their long service life and low maintenance needs reduce overall expenses for companies. |

| Resistance | Exhibiting excellent resistance to wear, corrosion, and extreme temperatures, steel bushings perform well in tough environments. |

| Versatility | Suitable for industries like automotive, aerospace, and construction, steel bushings adapt to a variety of operational requirements. |

| Environmental Impact | Many steel bushings are recyclable, contributing to sustainable practices in industrial applications. |

By leveraging these advantages, steel bushings continue to be a reliable and enduring component in countless mechanical systems worldwide. Their excellent performance and customizable features make them a preferred choice across multiple industries. Steel bushings play a critical role in ensuring that equipment maintains peak performance over time. Whether you’re looking for a standard solution or a custom design, steel bushings offer unmatched dependability for a diverse range of industrial needs.

Why Use a Bushing Instead of a Bearing?

While both bushings and bearings serve similar purposes, the choice between them often depends on the application. The use of bushings or ball bearings is a common decision point when selecting for a machine.

Key Differences Between Bushings and Bearings

Bushings are typically simpler in design compared to ball bearings, offering a cost-effective and low-maintenance solution for many applications. They are well-suited for environments where high loads and low rotational speeds are common, as they provide excellent load-carrying capabilities and wear resistance. Additionally, bushings operate quietly and are less sensitive to contamination, making them ideal for harsh conditions.

In contrast, ball bearings are designed for applications requiring precise motion and high-speed performance. They offer lower friction and are more efficient in reducing energy loss during operation. However, ball bearings are often more expensive and may require more maintenance to ensure longevity – especially in environments exposed to dirt or debris.

Bushings and bearings differ in several fundamental aspects, making each suitable for specific applications. Bushings, also known as plain bearings, are cylindrical components that provide a sliding motion between two surfaces. They typically operate without the need for rolling elements and can endure higher loads but tend to have lower speed limits compared to ball or roller bearings.

In contrast, ball bearings utilize rolling elements (balls) to reduce friction and support rotational motion. This design allows for higher speed capabilities and smoother operation, making ball bearings ideal for precision machinery and high-speed applications. However, they may require more maintenance and lubrication to function efficiently over time.

Understanding these differences allows engineers to choose a component that balances the trade-offs between durability, speed, load-bearing capacity, and ease of maintenance, ensuring optimal performance for the intended use.

The choice between a bushing and a bearing ultimately hinges on the specific requirements of the machinery and the operating conditions it will face.

| Feature | Ball Bearings | Alternative Components (e.g., Plain Bearings) |

| Motion Support | Rotational motion | Sliding motion |

| Speed Capability | Higher speeds due to reduced friction | Limited speed due to greater friction |

| Load-Bearing Capacity | Lower load tolerance | Higher load tolerance |

| Maintenance Requirements | Requires lubrication and maintenance | Often less maintenance-intensive |

| Suitability | Precision machinery, high-speed uses | Heavy-load, low-speed applications |

This table visually summarizes the key differences, helping to guide selection based on specific application needs.

Advantages of Bushings:

- Cost-Effectiveness: Bushings are generally more affordable and simpler to install than bearings.

- Versatility: Ideal for a wide range of applications, from shaft sleeve bushings in industrial settings to smaller systems in consumer products.

- Low Maintenance: Unlike ball bearings that may require lubrication, many bushings are self-lubricating.

- Shock Absorption: Bushings provide better damping capabilities in high-impact environments.

Limitations:

- Load and Speed: For high-speed or high-load applications, precision bearing bushing sleeves may be more suitable.

- Temperature Sensitivity: Certain bushing materials may not perform well under extreme temperatures, leading to deformation or a reduced lifespan. High temperatures can cause swelling or warping, while low temperatures might result in brittleness.

- Wear and Tear: Over time, bushings can experience wear, especially when used in applications with poor alignment or insufficient lubrication in non-self-lubricating types. This wear can lead to oscillation or vibration issues.

- Precision Limitations: Compared to bearings, bushings may lack the precision needed for applications requiring highly accurate rotational movement, making them unsuitable for some specialized machinery.

- Material Limitations: The performance of bushings can depend heavily on the material used. For example, plastic bushings may not provide the same strength or durability as metal ones in heavy-duty applications.

Bushings excel in applications where durability, vibration dampening, and cost considerations are critical.

Is a Bushing the Same as a Bearing?

No, a bush (short for bushing) and a bearing are not the same, although they share similar functions in reducing friction and facilitating motion. A bushing, such as a steel bushing sleeve, is a simple cylindrical component, whereas a bearing contains rolling elements (like balls or rollers) to support higher speeds and loads.

Key Differences:

- Design: Bushings are solid components, such as stainless steel sleeve bushings. Bearings contain movable parts and are designed for rotational precision.

- Applications: Bushings are used in moderate-speed and load settings. Bearings are preferred for high-speed, precision requirements.

- Maintenance: Many bushings are self-lubricating, while bearings often require ongoing lubrication.

Both components are essential in their respective fields, but steel bushings stand out for their simplicity, reliability, and cost-effectiveness.

What is the Best Material for Bushing?

The selection of bushing material depends on the specific application. Common materials include bronze, graphite composites, and stainless steel. Among these, stainless steel bushings are widely regarded as one of the best choices for demanding conditions.

Why Stainless Steel?

- Corrosion Resistance: Perfect for applications exposed to moisture or chemicals.

- High Strength: It withstands heavy loads without deforming.

- Durability: Long-lasting even in high-friction settings.

Applications of Stainless Steel Bushings

Stainless steel bushings excel in a variety of applications due to their superior properties. They are commonly used in industrial machinery, automotive components, and marine equipment, where their resistance to corrosion and durability ensures reliable performance. For example, in the automotive industry, stainless steel bushings are implemented in suspension systems and steering linkages to handle high stress and wear. Similarly, in marine environments, their resistance to saltwater corrosion makes them ideal for propeller shafts and other critical components. These qualities make stainless steel bushings a versatile and indispensable choice across multiple industries.

Other materials, such as bronze and graphite composites offer benefits like self-lubricating properties and reduced friction. However, for applications requiring both strength and corrosion resistance, stainless steel sleeve bushings are unmatched.

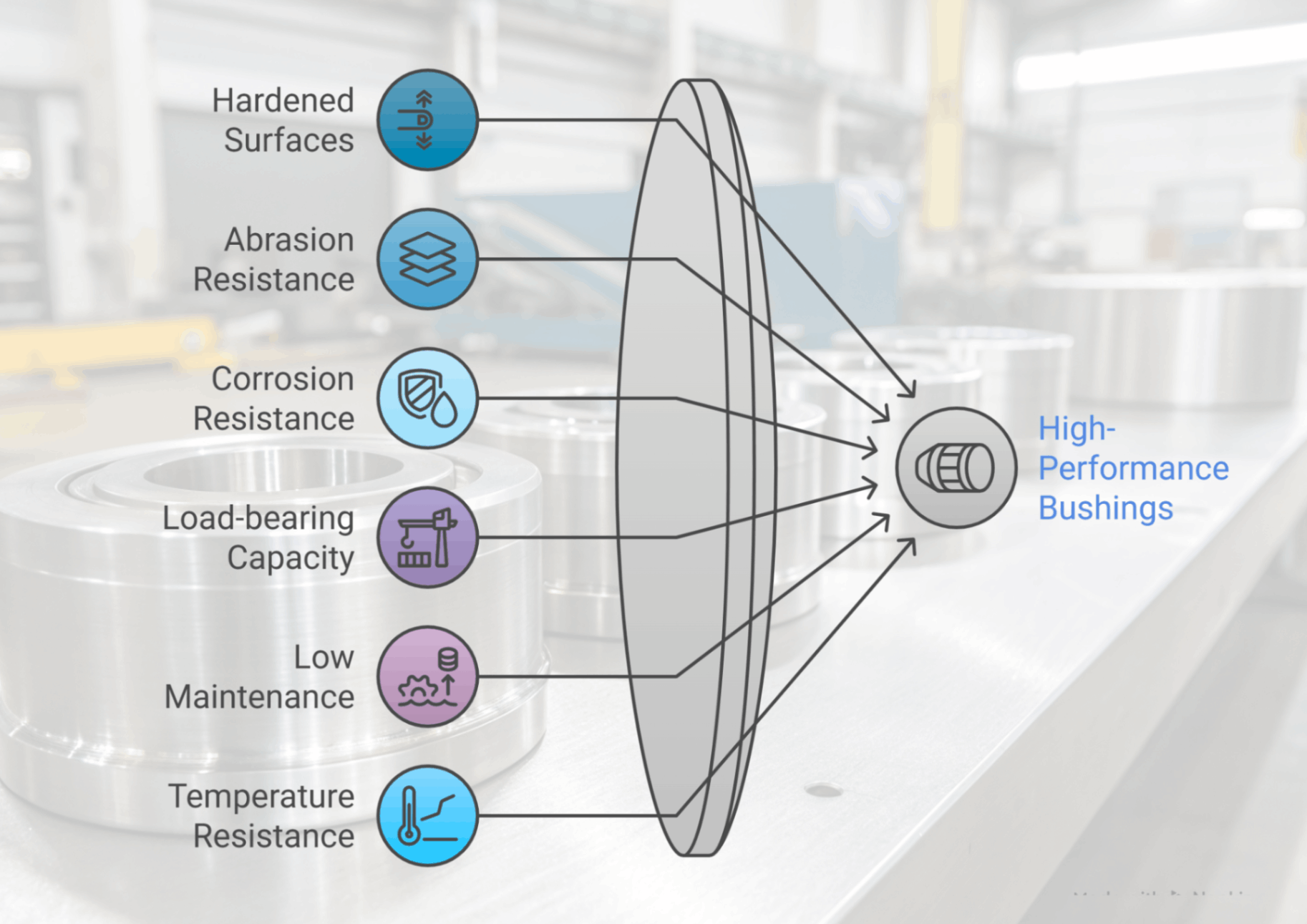

What is the Strongest Bushing Material?

Steel bushings, especially those made from hardened stainless steel, are among the strongest types of bushings available. They are highly durable and resistant to wear, making them the top choice for heavy-duty applications.

Features of the Strongest Bushing Materials:

- Hardened Surfaces: Prevents deformation under extreme pressure.

- Abrasion Resistance: Minimizes wear from repeated motion.

- Corrosion Resistance (for stainless steel bushings): Ensures longevity in harsh environments.

- Load-bearing capacity: High-strength bushings are designed to support significant loads without cracking or breaking, making them ideal for industrial machinery and equipment.

- Low Maintenance Requirements: Due to their durability and resistance to wear, these bushings often require less frequent maintenance, reducing operational downtime and costs.

- Versatility: Strong bushing materials like hardened stainless steel are suitable for a variety of applications, including the automotive, construction, and marine industries.

- Temperature Resistance: These materials can withstand extreme temperatures, ensuring reliable performance in both high-heat and freezing conditions.

- Precision Engineering: High-quality bushings are manufactured with tight tolerances, ensuring they fit perfectly and enhance the overall efficiency of machinery.

When designing components for high-impact or heavy-load scenarios, high-carbon or alloy steels are often used due to their exceptional toughness.

What Kind of Steel Are Drill Bushings Made Of?

Drill bushings, which guide drill bits during machining, are often made from hardened tool steels. Custom metal bushings used in drilling applications are usually crafted from materials such as:

- High-Carbon Steel: For enhanced wear resistance.

- Tool Steel: For applications requiring higher hardness and toughness.

- Stainless Steel: Offers corrosion resistance in addition to strength.

These bushings are designed to withstand the continuous stresses of drilling while maintaining precise alignment, ensuring accuracy in machining operations.

How Do You Harden Bushings?

Hardening bushings involves heat treatment processes that increase their surface strength and resistance to wear. Common techniques include:

- Carburizing: This adds carbon to the surface of the bushing to increase its hardness.

- Quenching and Tempering: Rapid cooling followed by controlled heating to balance hardness and ductility.

- Nitriding: This introduces nitrogen to the surface, creating a hardened layer with excellent wear resistance.

Hardened bushings, such as shaft sleeve bushings, are ideal for demanding applications where durability is critical.

Steel bushings play an integral role in improving machinery performance, extending equipment life, and ensuring reliability. With tailored options such as stainless steel flanged bushings and custom metal bushings, industries have access to versatile solutions suited for diverse applications.

Whether you are working on a new project or looking to enhance an existing system, we’re here to provide dependable solutions that support your goals, improve efficiency, and maximize performance. With SC Industries as your partner, you can trust that you are getting more than just parts; you are getting a commitment to excellence and success.