Steel bushings play a critical role in many mechanical applications, offering durability and strength to reduce friction and wear between moving parts. They are commonly used in industries such as automotive, aerospace, and manufacturing, where reliability and precision are essential.

But what type of steel is used for bushings? Engineers prioritize materials that balance strength, machinability, and corrosion resistance to meet specific operational needs. Factors such as load capacity, environmental conditions, and expected lifespan influence the choice of steel. Different types of steel come into play, each designed for particular performance demands to ensure the bushings can withstand rigorous use while maintaining optimal functionality.

What material is used for bushings?

Bushings can be made from a variety of materials depending on usage, but steel remains a top choice for its superior strength and reliability. Certain shaft bushing sleeve applications require hardened steel varieties for high-impact or load-bearing purposes, while softer steel grades may suffice for low-impact systems.

One of the most common materials is carbon steel, often used in standard applications where strength is the main factor. Alloy steels, which incorporate elements like chromium or nickel for added benefits, are invaluable when corrosion resistance and toughness are a priority. Stainless steel, known for its corrosion resistance, is frequently employed in environments exposed to moisture or chemicals. These tailored material options make steel bushings adaptable to numerous industries, from automotive to industrial manufacturing.

Which metal is good for making bushes?

Various metals are suitable for bushings, but steel stands out due to its versatility and resilience. Stainless steel and alloy steels are particularly effective at balancing durability and resistance to environmental factors. For specialized needs, transformer cores often use laminated silicon steels, while transformer bushings use insulating materials such as porcelain or resin-impregnated paper to ensure electrical insulation

Additionally, bronze is another common material used for bushings, especially in applications requiring low friction and high wear resistance. Its ability to withstand heavy loads and operate efficiently with minimal lubrication makes it a preferred choice in machinery and industrial equipment.

While metals like bronze or brass are used in some low-friction applications, they sometimes lack the strength required for heavy-duty systems. By contrast, steel offers a high degree of customization in its composition, allowing manufacturers to fine-tune the properties of bushings to specific operational requirements. This flexibility makes steel a superior option for demanding tasks requiring both precision and resilience.

What is the best material for steel bushings?

The best material for steel bushings depends on the operational conditions they are deployed in. For example:

- High Load Applications: High-carbon steel, hardened for strength, performs exceptionally under intense pressures.

- Corrosive Environments: Stainless steel bushings are ideal due to their ability to resist rust and chemical damage.

- Shock and Impact Resistance: Alloy steels infused with chromium or molybdenum provide enhanced strength and durability under extreme impacts.

For industry professionals seeking which material is best for steel bushings, it often comes down to weighing factors like wear resistance, machinability, and long-term reliability. You might choose carbon steel for cost efficiency or stainless steel when facing harsh environmental conditions. By selecting the proper steel composition, companies ensure optimal part performance and prolonged service life.

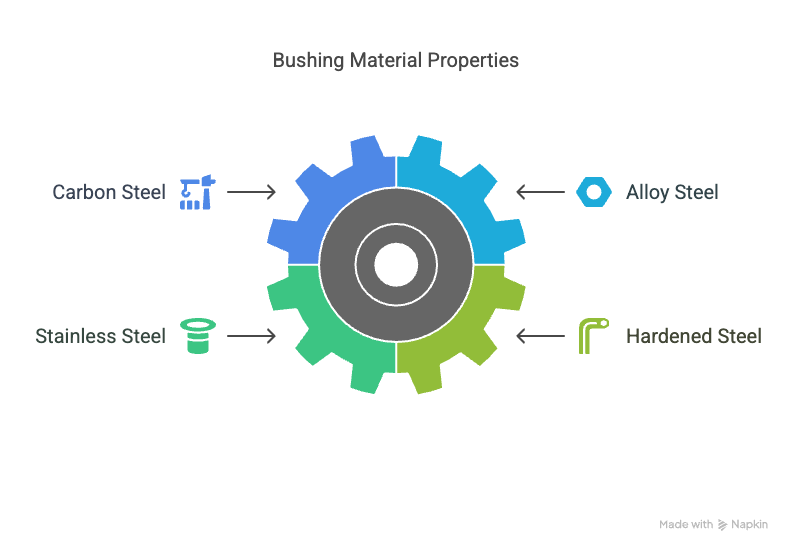

Common Steel Types for Bushings

Various types of steel are used in bushing applications, tailored to the unique demands of each system:

- Carbon Steel: A general-use material, carbon steel bushings offer an excellent balance of cost and performance for everyday applications. They are a solid choice for applications with low to moderate stress.

- Alloy Steel: More durable than carbon steel, alloy steels such as 4140 are often used in high-impact systems due to their toughness and wear resistance.

- Stainless Steel: Renowned for its ability to resist rust, stainless steel dominates applications where bushings are exposed to moisture, chemicals, or extreme temperatures.

- Hardened Steel: When strength and rigidity are critical, hardened steels ensure minimal deformation under high loads. This makes them the strongest bushing material for suspension systems and other high-stress environments.

Engineers often select the type of steel based on a careful assessment of factors like load capacity, environmental exposure, and friction levels. By tailoring the steel to these specifications, manufacturers optimize mechanisms for both performance and longevity.

Conclusion

Selecting the best steel for bushings requires balancing factors like load-bearing capacity, corrosion resistance, and operational durability. Materials like carbon steel, alloy steel, and stainless steel offer varied benefits, ensuring there’s an option for virtually any application. Whether you’re designing bushings for heavy loads, moisture-resilient systems, or extreme environmental conditions, steel stands out as a reliable and adaptable material.

For further information on Steel Bushing, check out our comprehensive guide linked here.

Additionally, learn more about selecting the right bushing material for steel shafts to enhance your projects. For customized solutions or expert advice, contact our team today!