How Do You Harden Bushings?

Comments Off on How Do You Harden Bushings?

When it comes to industrial applications, Steel Bushings play a vital role in ensuring durability and the seamless operation of machinery. One question often asked is how the process of hardening improves bushings.

This blog will explore how bushings are hardened, why the process is necessary, and what factors influence the quality and performance of hardened steel sleeve bushings. By the end, you’ll have a clear understanding of why hardening is crucial and how it can enhance the lifespan of these essential components.

How Do You Harden Bushings?

Bushings, especially those made from steel, are subjected to various hardening processes to improve their durability and resistance to wear. But what does this involve? The hardening of bushings usually begins with the selection of the right grade of steel. Following this, the steel undergoes a heat treatment process that alters its physical and mechanical properties.

The heat treatment process typically involves:

- Heating: The bushing is exposed to a specific high temperature based on the type of steel used.

- Quenching: After heating, the bushing is rapidly cooled using a quenching medium like oil, water, or air.

- Tempering: To reduce brittleness and enhance toughness, the steel is reheated to a lower temperature and then cooled again.

These steps significantly strengthen the hardened steel sleeve bushings, ensuring they perform optimally under high stress and harsh operating conditions.

How Do You Harden Bearing Steel?

Bearing steel is most likely to be hardened after being formed and machined into the desired bearing shape and dimensions while it is still in a relatively soft (unhardened) state, making it easier to cut and shape precisely. The bearing components are subjected to heat treatment after they have been machined to near-final dimensions.

Here’s how it’s typically hardened:

- Carburization: This process adds carbon to the surface of the steel to improve its hardness and wear resistance.

- Induction Hardening: This method involves heating the surface of the bearing steel by electromagnetic induction, then quenching it rapidly. This creates a hardened exterior while maintaining a tough inner core.

- Cryogenic Treatment: Sometimes, the steel is cooled to sub-zero temperatures to relieve residual stress and enhance its structural integrity.

By following these steps, manufacturers ensure that bearing steel provides the longevity and reliability needed for crucial applications, such as used in Steel Bushing.

What Is the Best Steel for Bushings?

The choice of steel greatly influences a bushing’s performance and durability. Commonly used materials include:

- Carbon Steel: Known for its balance between strength and affordability, carbon steel works well for general applications.

- Stainless Steel: This is a preferred choice for environments prone to corrosion, offering both durability and rust resistance.

- Alloy Steel: With enhanced mechanical properties, alloy steel is ideal for high-stress, high-wear applications.

For the best results, many opt for hardened steel, particularly variants that have undergone meticulous heat treatments. Hardened steel sleeve bushings crafted from these materials can withstand extreme conditions, making them perfect for heavy-duty machinery in industrial settings.

What Is the Best Lubricant for Dry Bushings?

Lubrication is a critical factor in the performance of any bushing. For dry bushings – also known as self-lubricating bushings – the type of lubricant used must reduce friction and resist wear without requiring frequent re-application:

- Graphite-Based Lubricants: These are excellent for high-temperature applications as graphite can withstand heat while maintaining low friction levels.

- Oil-Impregnated Lubricants: A popular choice for dry bushings, these lubricants are infused into the bushing material itself, providing consistent lubrication over time.

- Molybdenum Disulfide: This is a solid lubricant suited for extreme pressure applications while offering prolonged protection.

When used in conjunction with Steel Bushing systems, the proper lubricant extends the life of the parts and ensures smoother operation. Selecting the right type also depends on the operational environment, so understanding needs is crucial for optimum performance.

Best Lubricant for Metal Bushings

While the above covers dry bushings specifically, it’s worth noting that for standard metal bushings, traditional lubricants such as high-performance oils and greases are often used. These products create a protective film between the bushing and its mating surface, reducing both friction and wear.

When selecting a lubricant, consider the following factors:

- Viscosity: Higher viscosity lubricants work better for heavy load applications.

- Temperature Tolerance: Ensure the lubricant can handle the thermal conditions of your application.

- Compatibility: Always check that the lubricant is chemical-compatible with the bushing material.

Conclusion

Hardening bushings through heat treatment processes like quenching, tempering, or carburization enhances their resistance to wear, extending their lifespan across various applications. From choosing the right steel type to understanding the lubrication needs of bushings, every step contributes to creating durable and reliable machinery components.

For industries relying on heavy-duty machinery, hardened steel sleeve bushings are a game-changer, offering unmatched longevity and performance. If your next project demands bushings that can withstand extreme wear and tear, consider exploring hardened steel options.

Explore our range of high-quality steel bushings specifically designed for industrial use. Contact our team today to learn more and find the ideal solution for your needs!

What is hardened steel bushings material?

Comments Off on What is hardened steel bushings material?

Hardened steel bushings are a crucial component in various mechanical systems, providing durability, precision, and reliability in industries ranging from automotive to heavy machinery. But what exactly is the material that makes these bushings so effective?

This article will explore the uses of steel bushings, what materials are ideal for high-performance applications, and why hardened bushings stand out as some of the toughest and most reliable components available.

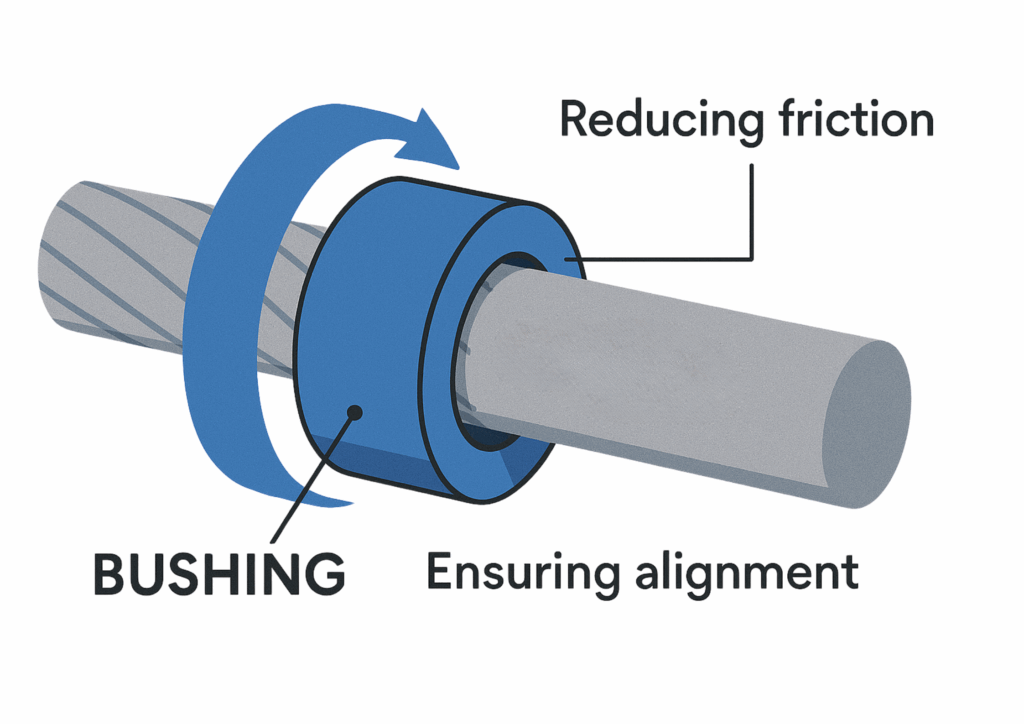

What are steel bushings used for?

Steel bushings are mechanical components designed to reduce friction, absorb wear, and align moving parts in machinery. Often playing a vital role in high-stress environments, these bushings act as protective liners between parts with relative motion, mitigating wear caused by metal-to-metal contact.

Key applications of steel bushings include:

- Supporting rotating shafts in engines, motors, and pumps.

- Providing a durable interface in pivot points of heavy equipment like excavators or cranes.

- Enhancing precision in manufacturing equipment by minimizing vibration and misalignment.

Additionally, hardened steel sleeve bushings are frequently used in systems requiring exceptional wear resistance and reliability. Their hard exterior ensures long service life even under extreme loads or severe operating conditions.

What material is used for high-performance bushings?

The choice of material for high-performance bushings directly impacts their functionality, durability, and ability to withstand challenging conditions. Among the most preferred solutions is hardened steel bushes.

Hardened steel bushes are made of alloys that undergo specific heat treatments to strengthen their outer surface while preserving interior flexibility. The enhancements in hardness improve their ability to endure constant friction and repeated loads without deformation.

Other materials like bronze, brass, or composite polymers may also be used for bushings in less demanding applications. However, they cannot match the strength, wear resistance, or longevity of hardened steel sleeve bushings in high-performance settings.

What is the best material for steel bushings?

When considering the best material for steel bushings, several factors come into play, including strength, wear resistance, and load-handling capacity. For most demanding industries, steel bushing material treated with heat-hardening processes consistently outperforms other options.

Why hardened steel is ideal:

- Exceptional wear resistance: The hard outer layer minimizes wear and tear, even when exposed to abrasive conditions.

- High strength: It can endure substantial loads without deforming or cracking.

- Corrosion resistance: Certain types of hardened steel – such as stainless steel alloys – offer excellent resistance to rust or chemical damage.

Real-world example:

Heavy construction vehicles like bulldozers rely on hardened steel bushes for their pivot joints. These bushings allow smooth, repetitive joint movement while supporting the equipment’s weight and withstanding dirt, dust, and moisture.

The role of surface finish:

High-performance steel bushing material is often precision finished through processes like grinding and coating. This minimizes friction and further extends service life.

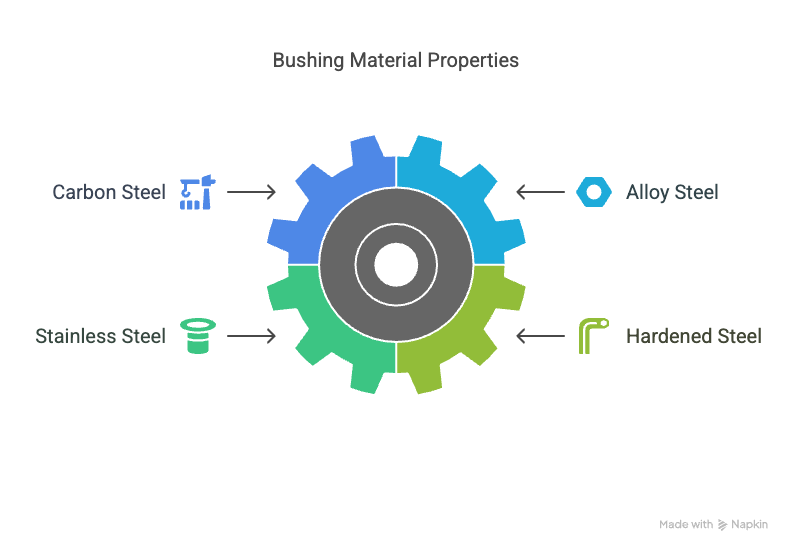

What type of steel is the hardest?

When it comes to identifying the hardest types of steel, it’s all about the manufacturing process. Hardened bushings are typically made from carbon or alloy steels that have undergone heat treatment to increase hardness. Here’s a closer look at what makes hardened steel stand out:

- Quenched and Tempered Steel:

This involves heating the metal to a high temperature, then rapidly cooling it in water or oil (quenching). The result? A significant boost in hardness and strength. - Tool Steel:

Often used for cutting tools and dies, this material boasts a unique balance of hardness and toughness. Its high carbon and alloy content makes it suitable for hardened bushings. - Martensitic Stainless Steel:

Known for its superior hardness, this type of steel combines the best of stainless and carbon properties, making it a strong contender for harsh environments.

Because of these treatments and material properties, hardened bushings offer unparalleled performance, even in severe operating conditions.

Conclusion

The right Steel bushing material can make or break the longevity and efficiency of mechanical systems. Hardened steel stands out for its toughness, wear resistance, and performance in demanding industries. Whether you’re supporting rotating shafts or protecting machinery from abrasion, investing in quality hardened steel sleeve bushings increases system reliability and longevity.

If you’d like to learn more about related products or applications, be sure to check out our comprehensive guide on Steel Bushing. For assistance with specific requirements about measurements, materials, or sizes feel free to contact us or explore our full catalog of metric hardened steel bushings.

What material is used for bushings?

Comments Off on What material is used for bushings?

Bushings are crucial components in machinery, serving as buffers to minimize friction and enhance performance. But what materials are bushings actually made of? The materials used are key to their durability, efficiency, and compatibility across applications.

At SC Industries, we specialize in delivering high-quality hardened bushings and custom components designed to meet your specific needs. Let’s explore what material is used for bushings and how we can partner with you to find the best solution.

Looking for precision steel bushings? Or need expert-crafted hardened steel sleeve bushings? SC Industries has decades of experience manufacturing these components with the highest level of accuracy. Contact us today for more details.

What is a bush bearing made of?

A bush bearing (also referred to as a plain bearing), typically consists of a cylindrical piece designed to reduce friction between moving parts. The material selection is tailored to specific applications, ranging from industrial machinery to automotive systems and beyond.

Common materials include bronze, brass, steel, polymer, and composites. Bronze remains a go-to option due to its wear resistance, while brass offers excellent anti-friction properties. For heavy-duty use cases, steel components are preferred for their lifespan and ability to handle high loads.

SC Industries manufactures high-performance steel bushings that undergo rigorous precision machining to achieve the required strength and reliability. For applications exposed to moisture or corrosive environments, materials such as stainless steel or composites are optimal choices. At SC Industries, we deliver customizable solutions tailored to match your operating conditions. Explore our portfolio examples here.

What materials are used for bushings?

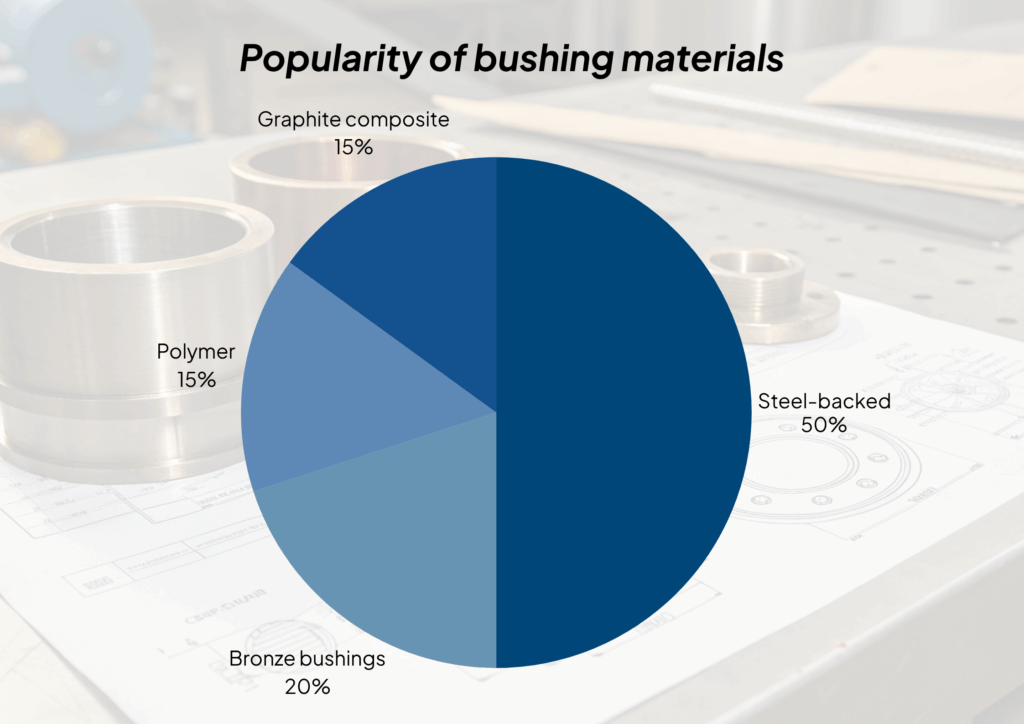

Types of bushing materials

Bushings are available in a range of materials designed to complement heavy-duty steel configurations, providing durability, reduced friction, and enhanced performance. Choosing the right bushing material depends on the application, operating environment, and load requirements. Here are some of the most commonly used materials:

- Steel-backed bushings: Combining the strength of a steel base with overlays like bronze or PTFE, these bushings are built for durability and efficiency. The steel provides structural support, while the overlay reduces friction, enhances wear resistance, and improves overall longevity – even in demanding applications.

- Bronze bushings: A time-tested choice, bronze bushings are ideal for systems that rely on consistent lubrication. Known for their excellent thermal conductivity and resistance to wear, bronze bushings are a reliable solution for various heavy-duty applications, especially in manufacturing and industrial machinery.

- Polymer bushings: Lightweight and versatile, plastic bushings are often made from materials like nylon or PTFE. They deliver low friction and offer self-lubricating capabilities, making them well-suited for applications where maintenance needs to be minimized. Additionally, they resist corrosion and are quieter during operation compared to their metal counterparts.

- Graphite composite bushings: Designed for extreme conditions, graphite composite bushings perform exceptionally well in high-temperature and high-load environments. They are self-lubricating and can withstand harsh operating conditions where traditional lubricants might fail, making them excellent for pairing with steel applications in industries like aerospace or heavy machinery.

At SC Industries, we specialize in precision-ground steel bushings tailored to meet your exact operating requirements. Whether you need standard bushings or custom-designed solutions, our team ensures top-tier quality to enhance your system’s performance and reliability. Learn more about our precision machining services.

Which material is best for bushings?

Deciding on the best material comes down to your application’s specific needs in reference to mechanical loads, temperature limits, and environmental factors. For industrial and heavy-duty systems, steel bushings often emerge as the most durable and reliable option. When evaluating options, it’s important to compare performance among several trusted steel bushing material suppliers to ensure you’re sourcing the right product for your system’s demands.

Partner with SC Industries for Steel Bushings

At SC Industries, we leverage 75+ years of expertise to produce hardened and ground bushings tailored to perfection. Whether you require strength for heavy loads or materials resistant to wear and tear, our extensive range has you covered. Contact us today for a custom solution.

What is the best metal for bushings?

While steel remains a leading choice, materials like bronze and brass are also utilized in applications requiring unique capabilities. However, in high-pressure or impact-heavy settings, hardened steel bushing components deliver superior performance.

Explore SC Industries’ Custom Bushings

SC Industries provides hardened steel sleeve bushings precision-engineered to suit various sizes and tolerances. We also specialize in weldable steel bushings, ideal for seamless installation and long-term reliability. No matter the requirement, our focus is on delivering products that reduce downtime and maximize operational efficiency. Check out our equipment capabilities here.

Custom Solutions by Size or Design

At SC Industries, we understand the importance of precision. That’s why we offer steel bushings by size and designs that meet your exact specifications. Whether you need small custom components or large-diameter bushings, we provide unparalleled quality and service. Browse our portfolio for examples of our work.

Why Choose SC Industries?

With over 75 years of experience producing metal bushings for demanding industries like heavy-duty vehicles and aerospace, SC Industries is your trusted partner for premium bushing materials and machining. We deliver on performance, longevity, and reliability with every project.

Request Your Quote

Whether you need advice on bushing materials or you’re ready to upgrade, SC Industries can help. Request a quote today!

Can stainless steel be used as a bushing?

Comments Off on Can stainless steel be used as a bushing?

When it comes to Steel Bushing applications, finding the right material is critical to achieving strength, durability, and performance. One question often asked is whether stainless steel is a suitable choice for bushings. Stainless steel is known for its anti-corrosive properties and versatility, but how does it measure up in applications where bushings are involved?

This article offers an in-depth look at the role of stainless steel in bushing design, exploring important facets such as material strength, durability, and lifespan. Before we break it down further, take note that hardened steel sleeve bushings are another well-regarded material within this domain.

What is the strongest bushing material?

Bushings are essential components in many mechanical systems. They reduce friction between moving parts and ensure smooth performance over time. When discussing strong materials for bushings, steel is often the dominant bushing material.

Steel is considered one of the strongest materials available for bushings. It delivers unparalleled strength and can withstand high levels of pressure and friction. However, stainless steel introduces an additional advantage. Its chromium content gives it resistance to rust, making it an excellent choice for applications exposed to moisture or corrosive environments such as marine machinery or food processing equipment.

Compared to other materials like bronze or nylon, stainless steel bushings also tend to last longer under heavy loads. This makes steel a bushing material highly competitive option for industries that prioritize strength.

What is the most durable bushing?

The durability of a bushing depends largely on the type of material you select for your application. Proper bushing material selection is crucial to balancing factors like wear resistance, heat tolerance, and ease of maintenance.

Stainless steel stands out for its durability in harsh environments due to its corrosion-resistant nature. It prevents excessive wear whether under lubricated or non-lubricated conditions. Whereas hardened steel bushings offer exceptional wear resistance and can be more durable in high-friction scenarios compared to stainless steel.

For example, in the transportation or industrial equipment sectors, bushings made from hardened steel may be the better choice because they can endure higher frictional stress. Nevertheless, applications exposed to weather or water – such as outdoor motors or maritime machinery – might benefit more from the durability of stainless steel. Striking the right balance in bushing material selection depends on the operational factors involved.

What type of steel is used for bushings?

There are different types of steel used in bushings, each offering unique advantages depending on the application. In this case we’re referring specifically to steel bushing materials and sizes, and their chemical composition.

Stainless steel, particularly the 300 and 400 series, is widely utilized for bushings. Grade 304 stainless steel is one of the most common types due to its high resistance to rust and excellent machinability. On the other hand, the 400 series, such as Grade 410, offers greater hardness and strength properties.

Another consideration when utilizing steel types is the cost factor. The price of steel used for bushings can vary depending on the type of steel.. While high-quality stainless steel can have a higher upfront cost, it often provides longer service life and less maintenance cost compared to lower-grade or alternative materials. Industries must assess whether the upfront costs of stainless steel justify its superior performance in the long term.

Ultimately, the selection of stainless steel grades for bushings hinges on their specific application. High-load systems may require hardened steel bushings, while elements exposed to corrosive conditions might call for higher chromium-content stainless steel.

What is the lifespan of a bushing?

The lifespan of a bushing is affected by multiple factors, including material composition, operating conditions, and maintenance practices. Bushings made from materials like steel and stainless steel often surpass alternatives like bronze or plastic due to their strength and resilience, especially in high-friction environments or challenging climate conditions.

With proper lubrication and maintenance, stainless steel bushings can last for years without needing replacement. Their rust resistance allows them to perform consistently in moisture-prone areas or high-humidity environments without losing structural integrity.

It’s essential to monitor wear rates, ensure appropriate lubrication is applied, and adhere to regular maintenance schedules to maximize the lifespan of a bushing. Some stainless steel bushings incorporate self-lubricating features, which further extend their operational life and reduce the need for frequent maintenance.

Final thoughts

Stainless steel is undoubtedly a versatile and robust option for bushings, providing excellent resistance to corrosion and a long operational lifespan. While hardened steel may outperform stainless steel in high-friction scenarios, the added corrosion protection of stainless steel makes it a compelling choice for applications exposed to harsh environments.

When choosing materials, it’s essential to align your selection with the specific needs of your operation. Whether it’s the strength of materials like steel used in bushing or the long-term benefits of stainless, the right choice can make all the difference in performance, durability, and cost-efficiency.

Need more guidance on solutions for your steel bushing applications? Explore more insights on Steel Bushing, and don’t forget to check out our solutions for hardened steel sleeve bushings for a closer look at alternative options.

What are the sizes of bushings?

Comments Off on What are the sizes of bushings?

Bushings are essential components designed to reduce friction between moving parts in a wide range of applications, from industrial machinery to automotive systems. Selecting the right bushing requires a clear understanding of bushing sizes, which vary depending on their specific use.

Available in both metric and imperial measurements, bushing diameters can range from just a few millimeters to several inches, with custom options also available for a precise fit. Key factors to consider when choosing a bushing include the inner and outer diameter, length, and material, as these directly impact performance and durability.

Whether you’re working with steel bushings or other types, addressing these considerations ensures optimal functionality for your application.

Are all bushings the same size?

No – bushings come in a wide range of sizes designed to fit specific applications. Depending on your project and the required precision, you might encounter different types, including custom drill bushings and steel flange bushing components.

Custom Drill Bushings

Custom drill bushings are specialized pieces tailored for specific uses. Frequently employed in industrial and manufacturing settings, they guide tools like drill bits with exceptional accuracy. Since these are custom-made, their dimensions can vary widely to meet specific machine requirements or application needs.

Flange Bushing Steel

Often constructed from steel, flange bushings are unique in their design, having a flange or lip on one end. Once installed, this feature prevents axial movement. Their size depends on the diameter and length required. They’re commonly used in automotive and heavy machinery, where precise alignment is critical.

What are the different bushing sizes?

Bushings come in multiple standard sizes and can also be uniquely tailored for specific designs. If you’re working with standard bushing sizes or need a steel bushing size chart, there are plenty of options to consider:

Standard Bushing Sizes

Standard sizes are widely available for industrial machines, cars, and more. For instance:

- Inner diameters typically range from 0.25 inches to 3 inches.

- Lengths and outer diameters vary depending on the housing and application.

These standard options simplify replacement processes and are cost-effective when customization isn’t needed.

Steel Bushing Size Chart

A steel bushing size chart is your go-to reference for selecting the right fit. Such charts provide detailed measurements, including:

- Inner diameter (ID)

- Outer diameter (OD)

- Overall length (OL).

For example, a standard steel bushing might list an ID of 1 inch, an OD of 1.5 inches, and an OL of 2 inches. These metrics ensure compatibility with your project’s specifications.

How are bushings measured?

Measuring bushings involves focusing on a few critical dimensions to ensure the component fits properly and functions as expected. Here’s what you need to consider:

- Inner Diameter (ID) – This is one of the most important measurements as it determines whether the bushing will fit around the shaft or rod.

- Outer Diameter (OD) – The outer diameter must match the housing or bore where the bushing will be seated.

- Length (or Height) – This refers to the overall length of the bushing. An improper length could lead to movement or instability.

Calipers, micrometers, or specialized measurement tools can be used to achieve accurate readings for each aspect.

How do you determine bushing size?

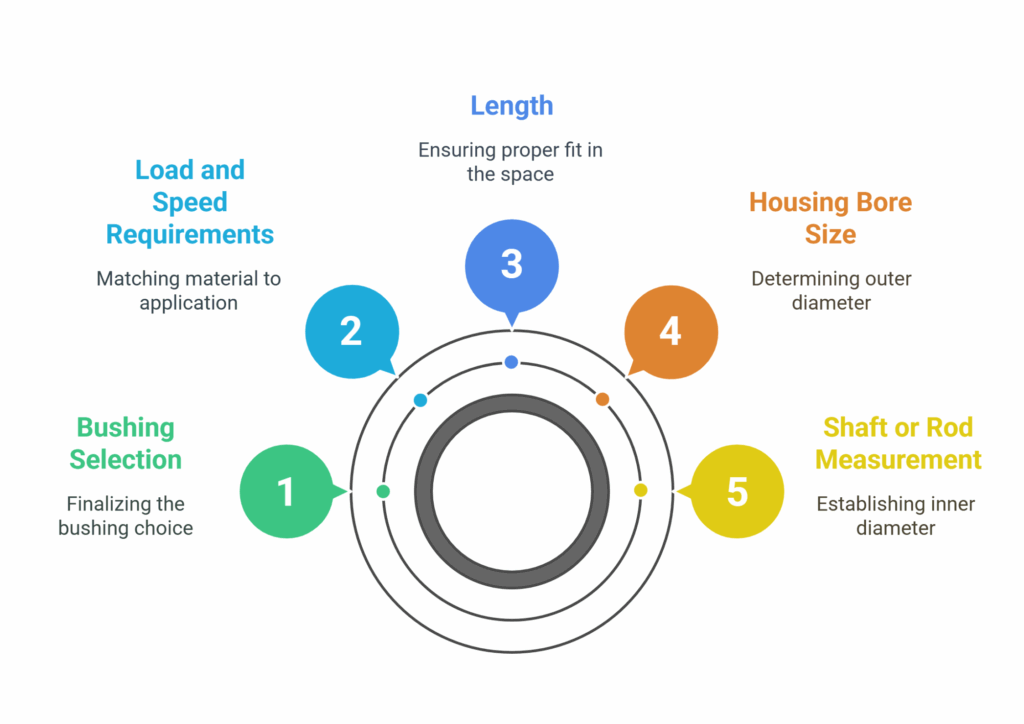

To determine the right bushing size, start with the application in mind. Since bushings must offer proper alignment and reduce wear between parts, obtaining the correct dimensions is critical.

Steps to Determine Bushing Size:

- Measure the Shaft or Rod

Use calipers to measure the outer diameter of the rod or shaft. This measurement becomes the inner diameter (ID) of the bushing. - Determine the Housing’s Bore Size

Similarly, measure the bore (housing or shell) where the bushing will fit. This value determines the outer diameter (OD) of the bushing. - Check the Length

The length of the space where the bushing will sit is your guide for the overall length or height of the bushing. - Confirm Load and Speed Requirements

Not all bushings are created equal. For example, high-speed applications may require lightweight materials, while heavy loads might necessitate steel construction.

Pro Tip

For complicated installations or unusual sizes, seek support from a steel bushing size chart or consult with manufacturers about custom solutions, like custom drill bushings.

Conclusion

Selecting the right bushing for your application is crucial to ensuring optimal performance and longevity. By carefully evaluating factors such as dimensions, material type, load, and speed requirements, you can make an informed choice that suits your specific needs. Remember to use resources like a steel bushing size chart or consult manufacturers for custom solutions when dealing with unique requirements. Contact a trusted supplier or manufacturer today to get started!.

What happens if bushings are worn out?

Comments Off on What happens if bushings are worn out?

Bushings are vital components used across all types of machinery—from industrial equipment to vehicles. Their job is to absorb shock, reduce friction between moving parts, and support smooth, controlled motion. Over time, however, bushings can wear out due to constant stress, exposure to heat, chemicals, or simply age.

Bushings are critical components in car’s suspension system, functioning as mechanical cushions that reduce friction and absorb shocks between moving parts. They help ensure a smooth, controlled ride by supporting rotating elements in a specific alignment and minimizing wear on related components.

But what happens when they wear out? Worn bushings can lead to unsettling noises, compromised handling, and even damage to adjacent parts. Worse, they can increase energy dissipation and vibration in your vehicle, shortening its overall lifespan. Let’s break down how to identify worn bushings, the risks of neglecting them, and the importance of timely replacement.

Steel Bushing and bushings are integral to this discussion, so exploring their role and condition is crucial. Check our detailed guides on Steel Bushing and bushings for more in-depth information.

How do I know if my bushings are worn?

Worn control arm bushings exhibit several symptoms, such as:

- Excessive vibrations while driving, especially when hitting bumps or uneven roads. Worn bushings are often less effective in absorbing shocks properly.

- Uneven tire wear, caused by a misalignment of the suspension as the bushings degrade.

- Erratic handling or steering, where the car feels less stable and harder to control – especially at higher speeds.

- A clunking sound when the suspension system activates, such as during braking or cornering.

These symptoms of bad control arm bushings signal that your vehicle’s suspension system is no longer functioning optimally. Early diagnostics can protect against further damage and costly repairs.

What do worn bushings sound like?

Sound is a primary indicator of worn bushings. Looking out for worn bushings symptoms in the form of noise can help you diagnose the issue early. Common sounds include:

- Clunking or thumping noises, particularly noticeable when driving over potholes or speed bumps.

- Creaking sounds while turning the steering wheel or during braking, as worn bushings struggle to effectively dampen the motion.

- Rattling or knocking noises caused by loosened bushings, which create instability between suspension components.

These distinctive sounds arise due to increased friction and the absence of proper lubrication, both of which are prevalent in worn bushings. If you hear such noises, schedule an inspection immediately.

How serious is a bad bushing?

Bad bushings are more than a minor annoyance; they can cause significant safety and performance issues. Their wear impacts the structural integrity of your vehicle in the following ways:

- Accelerated vibrations and energy dissipation occur, leading to reduced endurance of machine elements such as shafts and control arms. High vibrations can eventually damage surrounding systems as well.

- Safety risks may increase due to compromised vehicle handling, making it difficult to steer or brake effectively.

- Wear on adjacent components, since the control arm or suspension springs face unregulated stress when bushings fail.

- Reduced system efficiency, making your vehicle operate less smoothly while increasing power loss.

Studies of rotating machines suggest that excessive wear in bushings may also lead to self-excited vibrations that the vehicle itself generates, ultimately shortening its operational life. Timely replacements are essential to prevent irreversible damage.

Is it safe to drive with worn bushes?

Driving with worn bushes might seem manageable in the short term, but it introduces considerable risks to both you and your vehicle. Here’s a deeper understanding of the consequences:

- Compromised Safety

Worn bushings decrease the ability of the suspension system to maintain stability during turns or emergency braking. This instability can lead to accidents, especially at high-speed or during adverse weather conditions. - Rear bushings replacement cost

Replacing rear bushings can cost between $200 – $600 or more, depending on your car’s model. This expense is modest compared to the extensive repairs required if worn bushings contribute to control arm or suspension damage. - Driving with bad control arm bushings

Continuing to drive with failing bushings accelerates the degradation of core components. For instance, vibrations and slack can lead to abnormal wear in shaft necks and control arms, multiplying repair costs over time.

Research also highlights the inefficiencies created by increased friction and movement from having worn components. Addressing the issue early helps restore the original performance of your vehicle and extends its overall longevity.

Conclusion

Worn bushings are far more than a minor inconvenience. Ignoring symptoms of bad control arm bushings or second-guessing worn bushings symptoms can compromise both safety and performance, leading to costly repairs. Heavy vibrations, clunking noises, and steering instability all point to worn bushings that urgently need replacement.

With proper diagnostics, you can mitigate energy loss, premature wear on other parts, and safety hazards. Technologies like vibration signal analysis and predictive maintenance can help detect potential issues before failures become catastrophic.

Explore our comprehensive resources on Steel Bushing and bushings to better understand how to care for these vital parts of your vehicle. Don’t wait for a minor issue to escalate into a major problem. Schedule an inspection today, and ensure your vehicle stays in optimal condition!

Are Bushings Expensive to Fix?

Comments Off on Are Bushings Expensive to Fix?

Bushings are essential components in many types of machinery, serving to reduce friction, dampen vibration, and ensure smooth motion between moving parts. In the automotive industry, bushings play a particularly critical role in the suspension system, improving ride comfort, steering response, and overall vehicle stability.

If your car has been making strange noises or handling poorly, you might not be aware that bushings could be a cause of the problem. Bushings are vital components in your vehicle’s suspension system, helping to reduce friction between moving parts and providing a smoother ride. But when they wear out, it can lead to significant issues. Let’s explore whether fixing bushings is a costly endeavor and what you need to know about the process.

Why Regular Maintenance Matters

Given their pivotal role in vehicle performance, keeping an eye on the condition of your bushings is an important aspect of car ownership. Regular inspections as part of routine maintenance can help catch wear-and-tear early, saving you time and money in the long run. Addressing bushing problems promptly can also prevent more extensive damage to suspension and steering components.

What Happens If You Don’t Replace Bushings?

Ignoring worn bushings can lead to more than just a bumpy ride. Over time, their deterioration may cause damage to other parts of your suspension system, such as shocks, struts, or control arms, resulting in decreased performance and increased wear on your vehicle. This can also impact your car’s safety by reducing stability, handling, and braking efficiency, putting both you and other drivers at risk.

Worn bushings symptoms

There are several worn bushings symptoms to look out for. Common signs include:

- Unusual noises, such as clunking or squeaking, when driving over bumps or turning.

- Uneven tire wear, indicating that your suspension system isn’t functioning properly.

- Vibrations in the steering wheel, especially when driving at high speeds.

- Difficulty controlling the vehicle or a rough, uncomfortable ride.

Addressing these worn bushings symptoms early can save you money and prevent additional damage to your car.

Is It Expensive to Replace a Bushing?

The cost of replacing bushings varies depending on the type of bushings, the vehicle model, and the labor involved. It’s important to understand the potential expenses before committing to a repair.

Car bushings cost

Car bushings costs can range from $50 to $200 for the bushings themselves, depending on the material and quality. Some bushings are made from rubber, while others use more durable materials like polyurethane, which might come at a higher price.

Control arm replacement cost

If the bushings are integrated into larger components like the control arm, you may need to replace the entire control arm. The control arm replacement cost can range between $200 and $500 per arm, not including labor charges. This makes the repair more expensive than replacing standalone bushings.

Always account for labor costs when budgeting for this repair, which can vary significantly depending on your mechanic’s rates and the complexity of the job.

Is It Worth Replacing Bushings?

Replacing bushings may seem like an inconvenient expense, but it is often a worthwhile investment in your vehicle’s performance and security.

Car bushing replacement

The benefits of car bushing replacement go beyond just simple fixes—this maintenance step can significantly enhance your driving experience. Replacing worn or damaged bushings improves handling and stability, giving you better control over your vehicle – especially during turns or on uneven roads. It also ensures smoother, more comfortable rides by reducing vibrations and minimizing noise from the suspension system.

Additionally, fixing loose or damaged bushings can protect and extend the life of related components like control arms, tie rods, and shocks, which are critical to your car’s performance. By addressing bushing issues early, you can avoid more costly repairs down the line and keep your vehicle running safely and efficiently for longer periods.

Are Bushings Easy to Replace?

The difficulty of replacing bushings depends largely on their location within the vehicle. Some bushings, like those on sway bars, might be accessible and simpler to replace with basic tools. However, others, like control arm bushings, require significant disassembly and specialized tools, making the task more challenging.

Do-it-yourself experts with mechanical experience may save on labor by tackling certain bushing replacements themselves, but for more complex repairs, it’s better to leave the job to a professional. No matter the method, ensuring the proper fit and alignment of new bushings is key to achieving optimal performance.

Act now – don’t wait!

While replacing bushings can be an expense, addressing the issue promptly ensures your car’s longevity. Costs can vary depending on whether you need a simple car bushing replacement or a more extensive repair involving the control arm, but the benefits far outweigh the risks of ignoring worn components.

If you’re noticing worn bushings symptoms in your vehicle, don’t delay. Reach out to a trusted mechanic or explore more about Steel Bushing technology and maintenance in our related articles. Staying informed and being proactive can make all the difference.

Does Anyone Make Custom Steel Bushings?

Comments Off on Does Anyone Make Custom Steel Bushings?

Steel bushings are a crucial component in many industries, providing support, reducing friction, and ensuring the longevity of mechanical systems. But what happens when standard solutions don’t fit? You might find yourself asking, “Does anyone make custom steel bushings?”

The answer is yes! Custom bushings are widely available and tailored to specific needs. When searching for the best solution, it’s also important to consider the bushing material for steel shafts, which can significantly impact performance. This guide will answer your questions and explore the manufacturing process, materials, and industries that rely on custom steel bushings.

Can Stainless Steel Be Used as a Bushing?

Yes, stainless steel can be used to make bushings, often being chosen for its unique properties. Stainless steel is highly resistant to corrosion, making it an excellent choice for systems exposed to moisture or harsh environments. This includes marine equipment, outdoor machinery, and certain food processing systems where hygiene and durability are critical.

Additionally, stainless steel provides exceptional wear resistance in high-load and high-friction situations. It’s often the bushing material for steel shafts – applications where precision and longevity are priorities. However, while stainless steel offers significant advantages, other steel bushing materials might be more cost-effective or better suited to specific operational conditions, such as extreme heat or abrasive environments.

Ultimately, choosing the right material depends on your specific application. Discuss your requirements with a qualified manufacturer to determine whether stainless steel or another material is the best fit for your needs.

What Is the Process of Metal Bushing Manufacturing?

Producing metal bushings– including heavy-duty steel bushings – involves a detailed and precise process. Each step ensures the final product meets the required specifications for performance and durability. Here’s an overview of how steel bushings are made:

1. Initial Design and Specifications

Collaborating with engineers to develop a precise design begins the process. Factors such as operational loads, tolerance levels, and wear resistance are considered to ensure the bushing meets its intended function.

2. Material Selection

High-grade steel is often the material of choice due to its strength and durability. Manufacturers can also enhance heavy-duty steel bushings by applying coatings or heat treatments when required by the application.

3. Machining and Fabrication

Once the material is selected, the metal bushings are precision-machined using advanced manufacturing tools such as CNC equipment. This step ensures the bushings are crafted with exceptional accuracy and meet tight tolerances.

4. Heat Treatment

To improve strength and wear resistance, bushings undergo heat treatments such as tempering or quenching. This step is especially critical for heavy-duty steel bushing manufacturers that produce components for high-stress environments.

5. Quality Control

Before any bushing is delivered, it undergoes rigorous quality assurance testing. This includes checking for dimensional accuracy, material integrity, and performance characteristics.

This methodical approach allows manufacturers to create bushings that deliver long-lasting, reliable results in even the most challenging applications.

Looking for Custom Steel Components?

When equipment has unique design needs, standard options might not be enough. Custom steel bushings offer a precise fit and tailored functionality to meet specialized requirements.

Custom Steel Bushings

Custom steel bushings are ideal for applications requiring enhanced durability, corrosion resistance, or a precise fit. Heavy machinery, aerospace components, and industrial equipment often rely on tailored solutions to maximize performance and reduce downtime.

Additionally, coatings like zinc or nickel can be added to custom steel bushings to meet specific environmental challenges. For example, anti-corrosive coatings work exceptionally well in saltwater conditions- perfect for marine applications.

Custom-made Drill Bushings

Custom-made drill bushings are essential for drilling operations requiring extreme precision. These specialized bushings ensure alignment and maintain tool accuracy, reducing errors and material waste.

When ordering custom bushings, manufacturers provide consultation services to create components that meet your exact specifications- from material selection to final dimensions. This level of customization ensures your equipment performs flawlessly under challenging conditions.

Who Makes the Best Bushings?

Your specific requirements and the industry in which your business operates most often determine who makes the best bushings to suit your needs. Here are some key qualities to look for when selecting a manufacturer:

Expertise in Customization

The best manufacturers have extensive experience with custom bushings. Look for providers that understand the nuances of your industry and can offer tailored solutions for your systems. Whether you require heavy-duty steel bushings or custom-made drill bushings, partnering with an expert ensures superior results.

High-Quality Materials

Top manufacturers use only premium materials, with the ability to customize components for specific applications. Discuss your preferences- such as anti-corrosion coatings or heat treatments- with your supplier to ensure the final product performs as required.

Robust Quality Control

Seek out manufacturers with stringent quality assurance processes. Every custom steel bushing should be meticulously tested to meet precise dimensions, strength requirements, and functional performance.

Stellar Customer Support

Excellent customer support makes a world of difference when sourcing custom bushings. The best manufacturers will guide you through every step from design to delivery, ensuring your specific needs are met.

Conclusion

Custom steel bushings are an excellent solution for industries where standard parts simply won’t make the cut. Whether you’re dealing with extreme stress, unique tolerances, or challenging environmental conditions, investing in a custom solution ensures optimal performance.

For applications involving stainless steel, custom-made drill bushings, or heavy-duty steel bushings, consult with a reputable manufacturer to select the ideal material and design. From precision machining to tailored coatings, custom bushings allow your equipment to operate smoothly and efficiently for years to come. Whether your needs involve industrial machines, aerospace systems, or automotive components, the right manufacturer can fulfill even the most demanding specifications.

If you’re ready to learn more, consider collaborating with experts who specialize in custom bushings to enhance your equipment’s reliability and longevity.

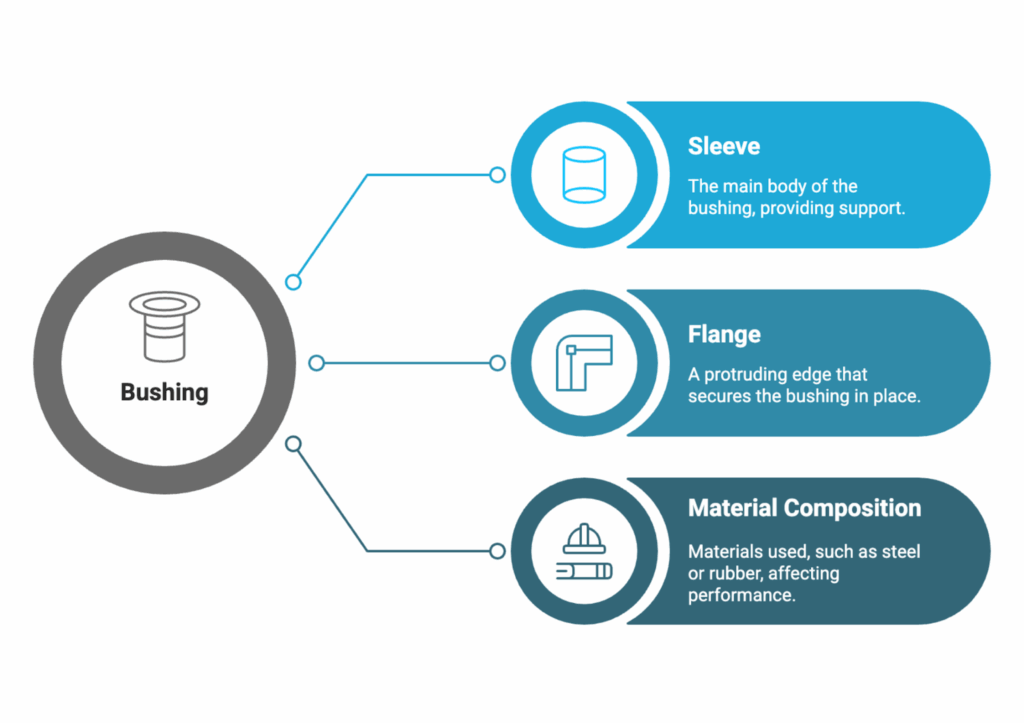

What Does a Bushing Do?

Comments Off on What Does a Bushing Do?

When tackling challenging mechanical or engineering systems, bushings play an essential role in ensuring smooth operation, reducing wear, and prolonging the lifespans of components. If the term leaves you puzzled, don’t worry—we’ll break it down! By the end of this post, you’ll understand what bushings are, what they do, and why they’re essential in so many applications.

Before we go further, be sure to explore detailed information about Steel Bushing and bushings by following our linked resources.

What is the Purpose of a Bushing?

To understand bushings, we must first explore their role in engineering. A bushing definition engineering refers to a cylindrical lining designed to reduce friction and wear between two surfaces in mechanical systems. Acting as a protective interface, bushings serve as support for moving parts, ensuring their motion remains smooth and controlled.

Bushings exert their usefulness across various industries. Whether it’s in automotive suspension, where they minimize vibrations, or heavy machinery, where they reduce shocks, bushings ensure systems operate effectively without unnecessary strain.

They’re also integral in robotics, aerospace, consumer electronics, and renewable energy systems – helping maintain alignment, absorb impact, reduce friction, and prevent metal-on-metal contact that could otherwise lead to mechanical failure, performance loss, or reduced efficiency in high-precision environments. Their compact design and material adaptability make them indispensable even in advanced or space-constrained applications.

For instance, in vehicles an engineering bushing definition typically refers to small, yet sturdy pieces that absorb noise and vibration as the car moves. Over time, they wear out but are easily replaceable, further showcasing their practical utility.

What’s the Difference Between a Bushing and a Bearing?

When discussing bushings, people often question their relationship to or differences from bearings. While there’s some overlap, understanding bushing vs bearing boils down to their specific applications and designs.

- Bushings are simpler components. They’re typically stationary sleeves, often made from robust materials like metal, rubber, or even polymers. Their main job is to reduce friction and isolate vibrations. For example, many machines have bushings installed in areas where motion is rotational or back-and-forth.

- Bearings are more complex. A bushing bearing often includes balls or rollers to allow for free movement with minimal friction. These are commonly used in situations where high-speed rotation is necessary, such as in engines or turbines.

To summarize, bushing vs bearing isn’t an argument about superiority; it’s about fitting the right component into its optimal role. A bush in a suspension system won’t work well in a high-speed motor, just as a complex bearing may be overkill and too costly for low-motion uses.

What Does a Bushing Look Like?

Bushings come in several shapes and materials, largely dependent on their function and intended location within a system. The most common forms include cylindrical and flanged bushings. Their outer surface often resembles a smooth sleeve, while the inner surface supports movement. Visually, they may seem unimpressive, but it’s this deceptively simple appearance that makes them so functional in diverse environments.

Steel bushings, rubber bushings, and bonded options are all popular types chosen according to an application’s heat resistance, durability, or flexibility requirements. For example, steel bushings withstand high pressures and temperatures, making them perfect for heavy-duty industrial applications. Alternately, rubber bushings are often utilized in lower-friction systems where absorption of noise and vibration is key.

Can I Drive with Bad Bushings?

Driving with worn-out bushings can lead to problems that may quickly escalate. While you might be able to drive for some time without replacing them, bad bushings present serious risks. Over time, they may compromise your vehicle’s suspension system causing poor handling, uneven tire wear, and increased vibrations.

Any of these signs may indicate your bushings are bad:

- You hear clunking or rattling noises from the vehicle’s suspension.

- The steering feels overly loose.

- There’s visible wear or cracking in the bushing material.

While driving with bad bushings for a short distance might seem manageable, prolonged neglect could result in significant suspension and wheel alignment issues. Address these problems early to prevent costly repairs and ensure a smooth, safe ride.

In Summary

Bushings might be small in size and straightforward in design, but their importance cannot be overstated. From reducing friction to absorbing vibration, these components are the unsung heroes of many industries. Whether you’re dealing with an engineering bushing definition or figuring out the best option between bushing vs bearing, understanding their applications will help you maintain your equipment better.

To learn more about the critical role bushings play or explore detailed specs of Steel Bushing, check out our comprehensive resources. Don’t ignore this critical detail in your equipment. Stay informed, stay efficient, and keep those systems running smoothly.

What type of steel is used for bushings?

Comments Off on What type of steel is used for bushings?

Steel bushings play a critical role in many mechanical applications, offering durability and strength to reduce friction and wear between moving parts. They are commonly used in industries such as automotive, aerospace, and manufacturing, where reliability and precision are essential.

But what type of steel is used for bushings? Engineers prioritize materials that balance strength, machinability, and corrosion resistance to meet specific operational needs. Factors such as load capacity, environmental conditions, and expected lifespan influence the choice of steel. Different types of steel come into play, each designed for particular performance demands to ensure the bushings can withstand rigorous use while maintaining optimal functionality.

What material is used for bushings?

Bushings can be made from a variety of materials depending on usage, but steel remains a top choice for its superior strength and reliability. Certain shaft bushing sleeve applications require hardened steel varieties for high-impact or load-bearing purposes, while softer steel grades may suffice for low-impact systems.

One of the most common materials is carbon steel, often used in standard applications where strength is the main factor. Alloy steels, which incorporate elements like chromium or nickel for added benefits, are invaluable when corrosion resistance and toughness are a priority. Stainless steel, known for its corrosion resistance, is frequently employed in environments exposed to moisture or chemicals. These tailored material options make steel bushings adaptable to numerous industries, from automotive to industrial manufacturing.

Which metal is good for making bushes?

Various metals are suitable for bushings, but steel stands out due to its versatility and resilience. Stainless steel and alloy steels are particularly effective at balancing durability and resistance to environmental factors. For specialized needs, transformer cores often use laminated silicon steels, while transformer bushings use insulating materials such as porcelain or resin-impregnated paper to ensure electrical insulation

Additionally, bronze is another common material used for bushings, especially in applications requiring low friction and high wear resistance. Its ability to withstand heavy loads and operate efficiently with minimal lubrication makes it a preferred choice in machinery and industrial equipment.

While metals like bronze or brass are used in some low-friction applications, they sometimes lack the strength required for heavy-duty systems. By contrast, steel offers a high degree of customization in its composition, allowing manufacturers to fine-tune the properties of bushings to specific operational requirements. This flexibility makes steel a superior option for demanding tasks requiring both precision and resilience.

What is the best material for steel bushings?

The best material for steel bushings depends on the operational conditions they are deployed in. For example:

- High Load Applications: High-carbon steel, hardened for strength, performs exceptionally under intense pressures.

- Corrosive Environments: Stainless steel bushings are ideal due to their ability to resist rust and chemical damage.

- Shock and Impact Resistance: Alloy steels infused with chromium or molybdenum provide enhanced strength and durability under extreme impacts.

For industry professionals seeking which material is best for steel bushings, it often comes down to weighing factors like wear resistance, machinability, and long-term reliability. You might choose carbon steel for cost efficiency or stainless steel when facing harsh environmental conditions. By selecting the proper steel composition, companies ensure optimal part performance and prolonged service life.

Common Steel Types for Bushings

Various types of steel are used in bushing applications, tailored to the unique demands of each system:

- Carbon Steel: A general-use material, carbon steel bushings offer an excellent balance of cost and performance for everyday applications. They are a solid choice for applications with low to moderate stress.

- Alloy Steel: More durable than carbon steel, alloy steels such as 4140 are often used in high-impact systems due to their toughness and wear resistance.

- Stainless Steel: Renowned for its ability to resist rust, stainless steel dominates applications where bushings are exposed to moisture, chemicals, or extreme temperatures.

- Hardened Steel: When strength and rigidity are critical, hardened steels ensure minimal deformation under high loads. This makes them the strongest bushing material for suspension systems and other high-stress environments.

Engineers often select the type of steel based on a careful assessment of factors like load capacity, environmental exposure, and friction levels. By tailoring the steel to these specifications, manufacturers optimize mechanisms for both performance and longevity.

Conclusion

Selecting the best steel for bushings requires balancing factors like load-bearing capacity, corrosion resistance, and operational durability. Materials like carbon steel, alloy steel, and stainless steel offer varied benefits, ensuring there’s an option for virtually any application. Whether you’re designing bushings for heavy loads, moisture-resilient systems, or extreme environmental conditions, steel stands out as a reliable and adaptable material.

For further information on Steel Bushing, check out our comprehensive guide linked here.

Additionally, learn more about selecting the right bushing material for steel shafts to enhance your projects. For customized solutions or expert advice, contact our team today!